- Precision Requirements

- Dimensional Accuracy: For critical parts, such as engine components, the dimensional tolerance should be controlled within ±0.005mm. For general – purpose parts, a tolerance of ±0.02mm is acceptable.

- Surface Finish: High – precision parts like optical components require a surface roughness of Ra ≤ 0.2μm. For mechanical parts, Ra ≤ 1.6μm is often sufficient to ensure proper fit and function.

- Production Efficiency Requirements

- Batch Processing: For large – batch production (over 1000 pieces), the CNC machining center should be able to achieve a production rate of at least 50 pieces per hour for simple parts and 10 – 20 pieces per hour for complex parts.

- Setup Time: The setup time for a new batch of parts should be minimized. Advanced CNC machining centers with automatic tool changers and quick – change workholding systems can reduce setup time to less than 30 minutes.

- Cost – effectiveness Requirements

- Material Utilization: Through optimized nesting and cutting strategies, the material utilization rate should be maximized. For sheet – metal parts, a utilization rate of over 80% can be achieved.

- Energy Consumption: Modern CNC machining centers are designed to be energy – efficient. By using high – efficiency spindles and intelligent power management systems, energy consumption can be reduced by 20 – 30% compared to older models.

- Technical Advantages

- Complex Geometry Machining: 5 – axis CNC machining centers can machine parts with intricate geometries in a single setup. For example, turbine blades with complex aerodynamic shapes can be machined with high precision, reducing the number of setups from 3 – 4 to just 1. This not only improves machining accuracy but also significantly increases production efficiency.

- High – quality Surface Finish: The ability to continuously adjust the cutting tool’s orientation during machining allows for a more uniform cutting process, resulting in a superior surface finish. Surface roughness values as low as Ra ≤ 0.4μm can be achieved, eliminating the need for extensive post – machining operations.

- Process Parameters

- Spindle Power: For machining tough materials like titanium alloys, a spindle power of at least 20 – 30 kW is required. For aluminum alloys, a spindle power of 10 – 15 kW is usually sufficient.

- Tool Path Optimization: Specialized CAM software is used to generate optimized tool paths. For 5 – axis machining, the software calculates the best tool orientation and cutting sequence to avoid collisions and ensure efficient material removal.

|

Process Feature

|

Typical Application Scenarios

|

Technical Highlights

|

|

High – speed Cutting

|

Mass production of aluminum alloy parts (e.g., automotive body components)

|

Increases machining speed by 3 – 5 times compared to conventional machining, reduces cycle time significantly

|

|

Fine – finishing HSM

|

High – precision parts (e.g., medical implants)

|

Achieves a high – quality surface finish with minimal heat – affected zone, improving part performance and durability

|

- Adaptive Control Systems: These systems monitor the machining process in real – time. For example, if the cutting force exceeds a preset limit, the system automatically adjusts the feed rate or spindle speed to prevent tool breakage and ensure stable machining. This can increase tool life by 30 – 50% and improve machining accuracy.

- Predictive Maintenance: By collecting data from sensors installed on the CNC machining center, such as vibration sensors, temperature sensors, and motor current sensors, predictive maintenance algorithms can predict potential equipment failures. This allows for proactive maintenance, reducing unplanned downtime by up to 40%.

- Design Optimization

- DFM (Design for Manufacturing) Analysis: Engineers review the part design to ensure it is manufacturable. For example, they check for appropriate draft angles, fillet radii, and wall thicknesses. By making design modifications early in the process, potential machining difficulties can be avoided, reducing production costs by 15 – 20%.

- Simulation and Prototyping: Using CAD/CAM software, virtual machining simulations are carried out to verify the machining process. 3D printing technology can be used to produce prototypes quickly, allowing for design validation and reducing the time to market by 30 – 40%.

- Process Planning

- Tool Selection: Based on the material properties and part geometry, the most suitable cutting tools are selected. For rough machining of hard materials, carbide – coated tools are often preferred, while for finish machining, diamond – coated tools can provide excellent surface quality.

- Cutting Parameter Determination: Optimal cutting parameters, including spindle speed, feed rate, and depth of cut, are determined through a combination of experience, material data, and machining simulation. This ensures efficient material removal while maintaining part quality.

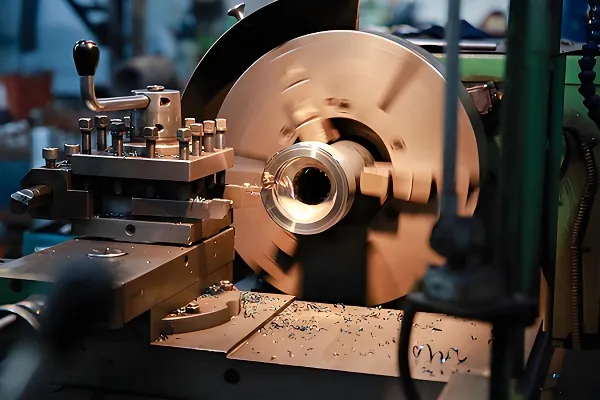

- Precision Machining Execution

- Setup and Calibration: Before machining, the CNC machining center is carefully set up and calibrated. The workholding device is aligned accurately, and the tool length and diameter are measured precisely. This ensures that the machining accuracy meets the design requirements.

- In – process Monitoring: During machining, various sensors are used to monitor the process. For example, acoustic emission sensors can detect tool wear, and vision systems can check the part dimensions in real – time. If any deviations are detected, the machining process can be adjusted immediately.

- Quality Control during Machining

- Sampling Inspection: Periodically, samples are taken from the production batch for inspection. Dimensional measurements are carried out using coordinate measuring machines (CMMs), and surface finish is checked using surface roughness testers.

- Statistical Process Control (SPC): SPC techniques are applied to monitor the machining process stability. By analyzing the variation in part dimensions over time, trends can be identified, and corrective actions can be taken to prevent quality issues.

- Comprehensive Quality Inspection

- Final Dimensional Inspection: The finished parts are thoroughly inspected for dimensional accuracy. All critical dimensions are measured multiple times to ensure consistency. Any parts that do not meet the tolerance requirements are reworked or scrapped.

- Functional Testing: For parts with specific functional requirements, such as gears and bearings, functional tests are conducted. For example, gear teeth are checked for proper meshing, and bearings are tested for smooth rotation and load – carrying capacity.

- Packaging and Delivery

- Customized Packaging: Parts are packaged according to their size, shape, and sensitivity. Delicate parts are protected with anti – static and shock – absorbing materials. Customized packaging boxes can also be provided with clear labeling for easy identification.

- Timely Delivery: With an efficient logistics management system, parts are delivered on time. Express shipping options are available for urgent orders, ensuring that customers receive their parts promptly.

- High – precision Components: For aerospace parts, such as aircraft engine components and structural parts, the highest level of precision is required. 5 – axis CNC machining centers are used to machine complex titanium alloy parts with tight tolerances (±0.003mm). Intelligent machining technologies ensure stable machining under high – temperature and high – stress conditions, meeting the strict quality requirements of the aerospace industry.

- Lightweight Design Parts: Aluminum alloy parts with complex hollow structures are commonly used in aerospace to reduce weight. HSM technology is applied to quickly remove large amounts of material while maintaining the required surface finish and dimensional accuracy.

- Mass – produced Parts: In automotive manufacturing, large – batch production of parts such as engine blocks, transmission cases, and wheel hubs is required. CNC machining centers with high – speed cutting capabilities and automatic pallet changers can achieve high – volume production with short cycle times. Advanced tool – management systems ensure continuous production without frequent tool changes.

- Customized Parts: For high – end or concept cars, customized parts are often needed. The part CNC machining center service can quickly produce prototypes and small – batch production parts based on the customer’s design, enabling rapid product development.

- Surgical Instruments: Medical surgical instruments require high precision and excellent surface finish. Stainless steel parts are machined using precision CNC machining centers with strict quality control. The parts are inspected for biocompatibility and sterility to ensure patient safety.

- Medical Implants: Titanium alloy implants are machined with extreme precision. 5 – axis machining allows for the creation of complex geometries that match the patient’s anatomy. Post – machining surface treatment, such as electro – polishing, is carried out to improve the implant’s biocompatibility and reduce the risk of rejection.