Functional Requirements

- Sealing performance: No leakage under negative pressure 0.08MPa for 30 seconds

- Temperature resistance: No cracks after 50 thermal cycles from -20℃ to 100℃

- Drop performance: No damage after dropping from 1.2m height

2. Mold Design Technology

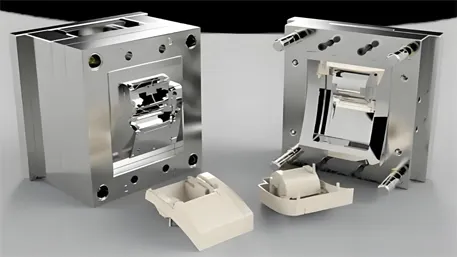

2.1 Mold Structure Design

Cavity Quantity Selection

- Single cavity mold: Suitable for small batch production or mold testing

- Two cavity mold: Balances production efficiency and mold cost

- Four cavity mold: Suitable for mass production

Parting Surface Design

- Position selection: At the maximum Contour of the product, facilitating demolding

- Shape design: Mainly flat parting surface, curved parting surface for complex products

- Sealing design: Width 4-6mm, fitting clearance ≤0.02mm

Gating System Design

Sprue

- Material: T10A steel, hardness 50-55HRC

Runner

- Cross-sectional shape: Circular or trapezoidal

- Surface roughness: Ra≤1.6μm

Gate Design

- Type: Pin gate or submarine gate

- Size: Pin gate diameter 0.8-1.5mm

- Position: Center of cup bottom or non-appearance surface of edge

- Quantity: One gate per cavity

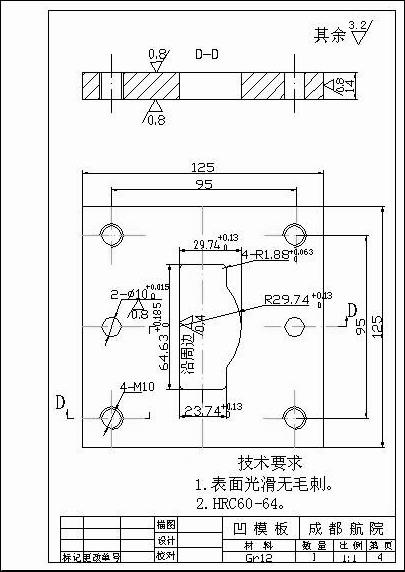

2.2 Molding Parts Design

Cavity Design

- Structure type: Integral or combined

- Size calculation: Part size × (1 + shrinkage rate)

- Surface treatment: Polished to Ra≤0.4μm

Core Design

- Structure type: Combined, facilitating processing and maintenance

- Cooling design: Built-in cooling water channels

- Surface treatment: Mirror polished to Ra≤0.2μm

Thread Molding Design

- Structure type: Threaded core or threaded cavity

- Demolding method: Rotational demolding or forced demolding

- Fitting clearance: 0.03-0.05mm

2.3 Cooling System Design

Design Principles

- Uniform cooling, temperature difference ≤5℃

- Water channels close to cavity, distance 10-15mm

- Avoid interference with other components

Water Channel Parameters

- Inlet temperature: 15-25℃

Special Designs

- Conformal cooling: 3D printed cooling channels for complex shapes

- Zonal control: Independent temperature control for different areas

- Turbulence design: Increase heat exchange efficiency

2.4 Ejection Mechanism Design

Ejector Pin Design

- Material: T8A steel, hardness 50-55HRC

- Distribution: Uniformly distributed on cup bottom

Ejector Plate Design

- Material: 45 steel, hardness 230-270HB

- Guidance: Guide pillar guidance to ensure smooth movement

Ejection Force Calculation

- Calculation formula: F = A×P×μ×K

- K: Safety factor (1.5-2.0)