What Are CNC Turning and Milling?

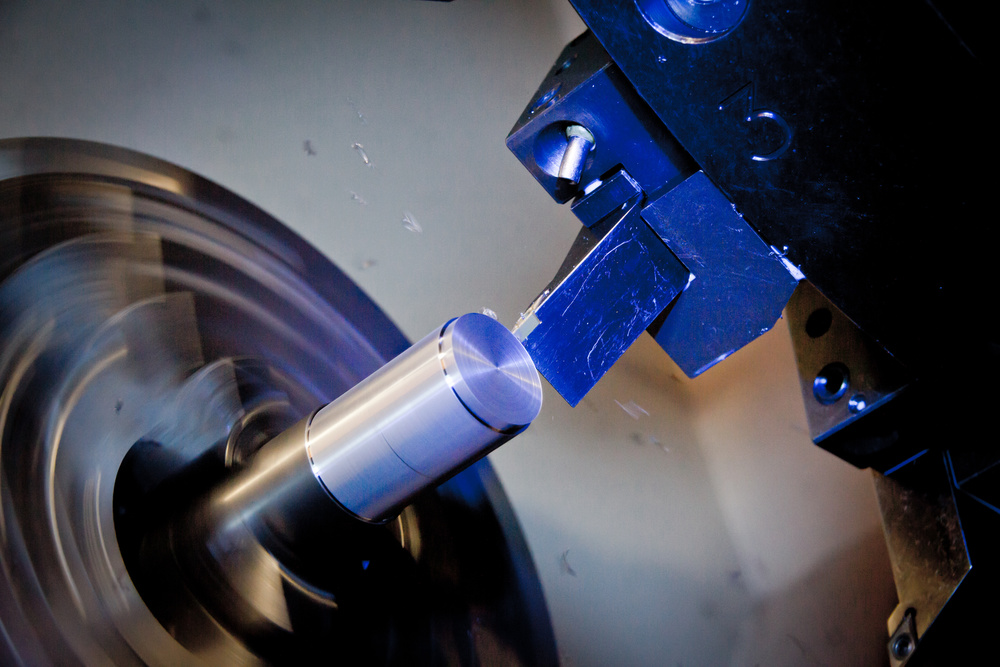

CNC Turning Process

- Excellent surface finishes (Ra 0.8-3.2 μm)

- Tight tolerances (±0.005-0.02 mm)

- High production efficiency for cylindrical parts

- Ability to create complex features like threads, tapers, and grooves

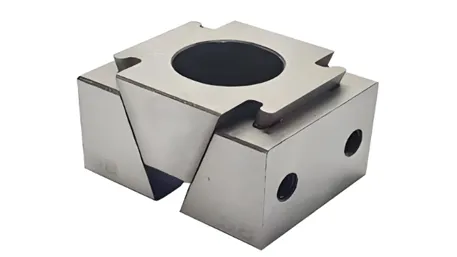

CNC Milling Process

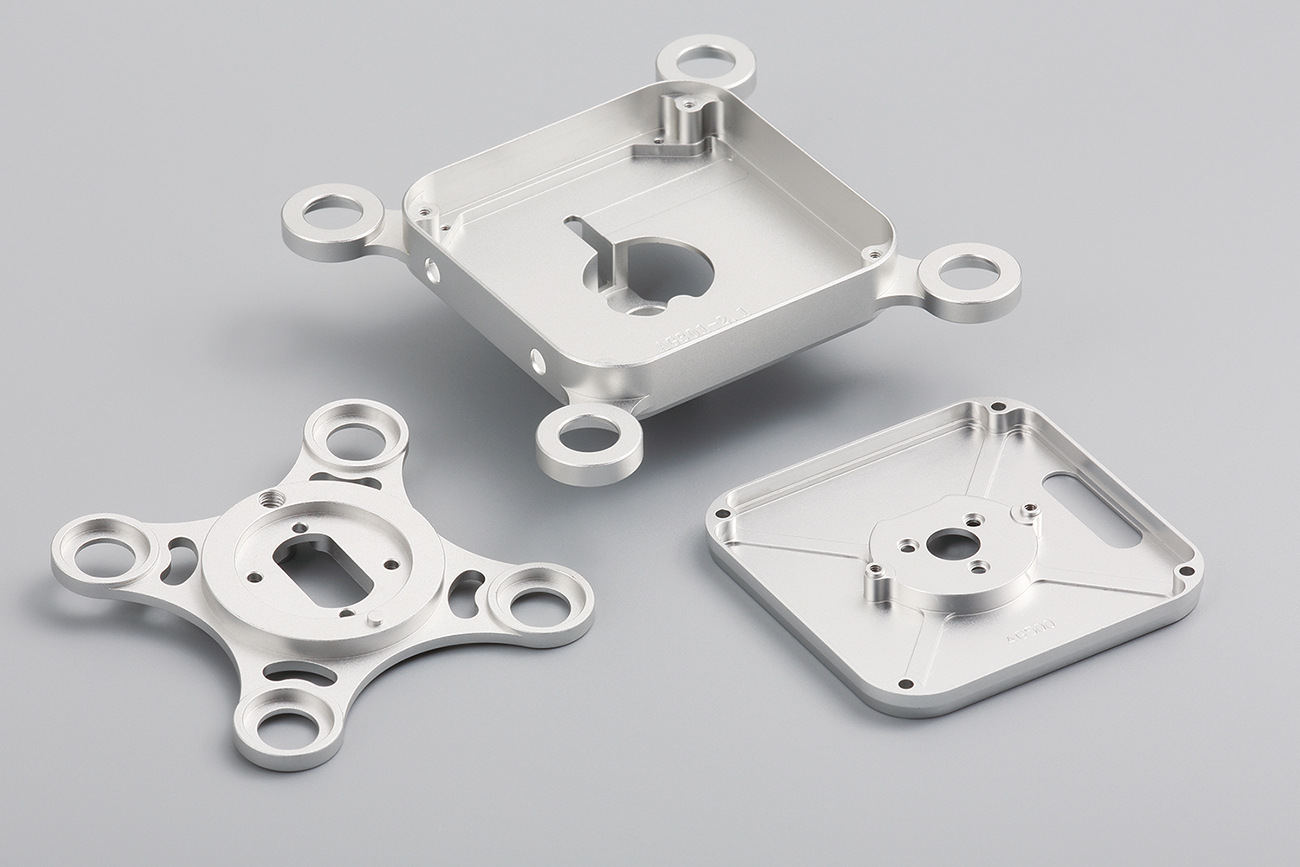

- Versatility in producing complex geometries

- High precision for both simple and intricate parts

- Ability to machine multiple surfaces in a single setup

- Compatibility with a wide range of materials

Machining Capabilities and Equipment

Multi-Axis CNC Machining

- Reduced setup time and improved accuracy

- Ability to machine complex curved surfaces

- Enhanced tool reach for deep cavity machining

- Superior surface quality and finish

- Maximum turning diameter: Up to 650 mm

- Maximum turning length: Up to 1,500 mm

- Spindle speeds: Up to 6,000 RPM

- Tool turret capacity: 12-24 tools

- Sub-spindle for complex part machining

Milling Specifications

|

Machine Type

|

Workpiece Size

|

Spindle Speed

|

Feed Rate

|

|

3-axis Mill

|

914 x 609 x 330 mm

|

Up to 12,000 RPM

|

20 m/min

|

|

5-axis Mill

|

406 x 406 x 406 mm

|

Up to 15,000 RPM

|

30 m/min

|

|

Vertical Machining Center

|

1,200 x 600 x 600 mm

|

Up to 10,000 RPM

|

25 m/min

|

Machinable Materials

Metal Materials

- 6061-T6: Excellent strength-to-weight ratio, corrosion resistant

- 7075-T6: High strength, ideal for aerospace applications

- 2024-T3: Good fatigue resistance, used in aircraft structures

- Carbon Steel: 1018, 1045 for general purpose applications

- Alloy Steel: 4140, 4340 for high strength requirements

- Stainless Steel: 304, 316 for corrosion resistance

- Tool Steel: H13, S7 for mold applications

- Titanium: Ti-6Al-4V for aerospace and medical applications

- Inconel: High temperature resistance for engine components

- Brass: Excellent machinability for precision parts

- Copper: Good conductivity for electrical components

Plastic Materials

- Acetal (Delrin): Excellent dimensional stability

- PEEK: High temperature resistance, biocompatible

- Nylon: Good wear resistance and strength

- PTFE (Teflon): Chemical resistance, low friction

- ABS: Impact resistant, used in consumer products

Surface Treatment and Finishing

Surface Finishing Options

- Sandblasting: Creates uniform matte surface

- Polishing: Achieves mirror-like finishes (Ra 0.02-0.05 μm)

- Grinding: Improves flatness and surface quality

- Honing: Enhances surface finish and dimensional accuracy

- Anodizing: Provides corrosion resistance and decorative finish

- Chromate Conversion: Improves paint adhesion and corrosion resistance

- Passivation: Enhances stainless steel corrosion resistance

- Phosphating: Prepares surfaces for painting or powder coating

- Nickel Plating: Improves wear resistance and corrosion protection

- Chrome Plating: Provides hard, durable surface

- Zinc Plating: Economical corrosion protection

- Gold Plating: For electrical conductivity and aesthetics

Applications and Typical Parts

Aerospace Industry

- Engine components: turbine blades, housings, manifolds

- Structural parts: wing fittings, landing gear components

- Avionics enclosures and brackets

- Fuel system components

- Tolerances as tight as ±0.001 mm

- Material traceability and certification

- Compliance with AS9100 standards

- Strict quality control and documentation

Automotive Industry

- Engine parts: cylinder heads, crankshafts, connecting rods

- Transmission components: gears, shafts, housings

- Suspension parts: control arms, knuckles, brackets

- Custom performance parts

- IATF 16949 certification

- PPAP documentation

- JIT delivery capabilities

- Cost-effective high-volume production

Medical Industry

- Surgical instruments and tools

- Implantable devices

- Medical device housings

- Diagnostic equipment components

- Biocompatible materials

- Ultra-precision machining (±0.0005 mm)

- Cleanroom manufacturing capabilities

- FDA compliance

Electronics Industry

- Heat sinks and thermal management parts

- Connector housings and pins

- Enclosures for electronic devices

- Custom brackets and mounting hardware

Quality Control and Inspection

Quality Assurance System

- ISO 9001:2015

- AS9100D (aerospace)

- IATF 16949 (automotive)

- ITAR registration

- Coordinate Measuring Machines (CMM): Accuracy up to ±0.0005 mm

- Optical Comparators: For complex shape verification

- Surface Roughness Testers: Measures Ra, Rz, Rq parameters

- Hardness Testers: Ensures material properties

- Vision Inspection Systems: Automated defect detection

Quality Control Process

- Incoming Material Inspection: Verify material certification and properties

- In-Process Inspection: Regular checks during machining operations

- First Article Inspection (FAI): Complete dimensional verification

- Final Inspection: Comprehensive testing before shipment

- Documentation: Detailed quality reports and certificates of conformity

How to Choose a CNC Machining Supplier

Technical Capabilities

- Equipment: Ensure they have the right machines for your parts

- Material Expertise: Verify experience with your specific materials

- Tolerance Capabilities: Confirm they can meet your precision requirements

- Process Capabilities: Check for multi-axis machining, Swiss turning, etc.

Quality Assurance

- Certifications: Look for ISO 9001, AS9100, IATF 16949

- Inspection Equipment: Ensure they have modern quality control tools

- Quality Processes: Ask about their inspection and documentation procedures

- Traceability: Verify material and process traceability capabilities

Experience and Reputation

- Industry Experience: Look for expertise in your specific industry

- Customer References: Request and check customer testimonials

- Project Portfolio: Review examples of similar work

- Years in Business: Consider established suppliers with proven track records

Service and Support

- Engineering Support: Look for design for manufacturability (DFM) assistance

- Communication: Ensure clear and responsive communication

- Lead Times: Verify they can meet your delivery requirements

- Flexibility: Check their ability to handle design changes and rush orders

Cost Considerations

- Competitive Pricing: Compare quotes from multiple suppliers

- Value-Added Services: Consider additional services that add value

- Total Cost: Look beyond initial price to consider quality and reliability

- Payment Terms: Evaluate flexible payment options

Get a Custom CNC Machining Quote

How to Request a Quote

- Upload Your CAD Files: We accept all major formats (STEP, IGES, STL, DWG, DXF)

- Specify Requirements: Material, quantity, tolerances, surface finish

- Get Instant Feedback: Our engineering team will review your design

- Receive Quote: Competitive pricing with detailed breakdown

- Start Production: Once approved, we begin manufacturing immediately

Why Choose Our CNC Machining Services

- Fast Turnaround: Standard lead times 5-15 days

- Competitive Pricing: Cost-effective solutions for all volumes

- Engineering Support: Expert DFM advice to optimize your design

- Quality Guarantee: 100% satisfaction or your money back

- Global Shipping: Worldwide delivery with tracking