| Materials |

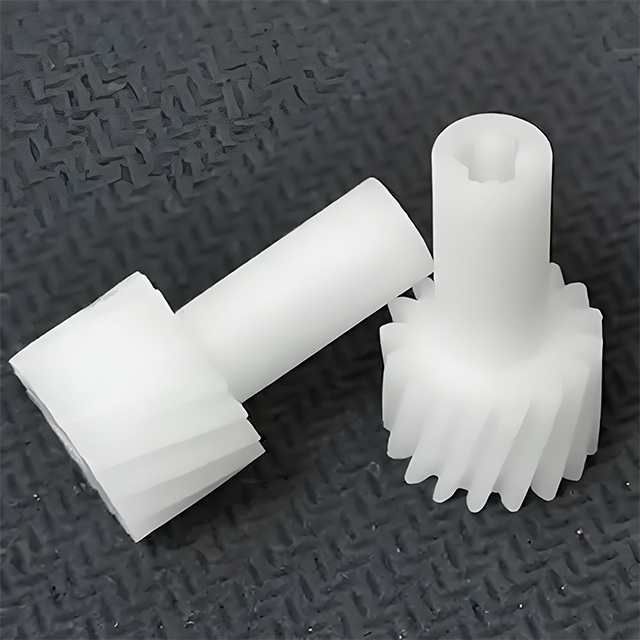

PA11, PA12, PA12GB nylon powder; supports ABS/PA66/PP/PC and other plastics/metals |

| Color |

Black (custom colors available) |

| Processes |

SLS (Selective Laser Sintering), MJF (Multi-Jet Fusion) 3D printing; supports FDM/SLA/others |

| Precision |

Tolerance: ±0.005mm, special areas: ±0.002mm |

| MOQ |

1 piece |

| Sample Lead Time |

1-7 days |

| Production Lead Time |

1-30 days (negotiable based on order volume) |

| Surface Treatments |

Abrasive polishing, electroplating, vapor smoothing, sandblasting, etc. |

| Application Areas |

Industrial gears, automotive parts, aerospace, medical devices, precision machinery |

| Certifications |

ISO 9001 |

| Design Support |

Accepts 2D/PDF/CAD, 3D/IGES/STEP drawings; offers 3D scanning & reverse modeling |

| Packaging |

Carton boxes, wooden cases, pallets (standard size: 15×15×15 cm, weight: 0.35 kg) |

| Shipping Methods |

Sea freight, air freight, DHL/UPS/FedEx, etc. |

| Factory Qualifications |

25+ years of experience, 100+ 3D printers (metal/ceramic included), 1,000,000 pcs/month capacity |

| Quality Control |

100% full inspection (CMM, projectors), quality inspection reports provided |