Precision machined small parts are those parts that are small in size, complex in shape and require very high accuracy. The following is a detailed description and explanation of precision machined small parts:

1.Definition

Precision machined small parts, as the name suggests, refers to small parts manufactured through precision machining techniques. These parts usually have tiny dimensions and complex shapes, and at the same time require extremely high machining accuracy and surface quality.

2. Characteristics

High accuracy: the primary characteristic of precision machined small parts is their high accuracy requirements. The manufacturing tolerances of such parts are usually very small and need to be at the micron or even nanometer level.

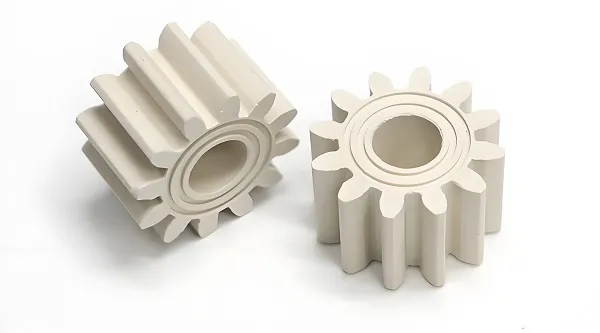

Complex shapes: Due to functional requirements, these parts often have complex geometries, such as tiny gears, holes, grooves, and so on.

High quality surfaces: The surface quality of precision machined small parts is also very important and often requires a mirror grade finish to minimize friction and wear.

High Material Requirements: In order to meet the requirements of high precision and high strength, precision machined small parts are usually made of high quality materials, such as stainless steel, titanium alloys, ceramics and so on.

3.Application Scenarios

Precision machined small parts are widely used in many fields, including but not limited to:

Electronic equipment: such as smart phones, notebook computers in the micro-connectors, sockets and switches.

Medical devices: such as micro tools for surgery and endoscope accessories.

Aerospace: small components in various sensors, actuators used in high altitude or space environments.

Automotive industry: Various high-precision components from engines to airbag systems.

Measuring instruments: such as thermometers, pressure gauges, sensitive components within flow meters.

4. Processing methods

Precision machining of small parts are usually manufactured using the following processing methods:

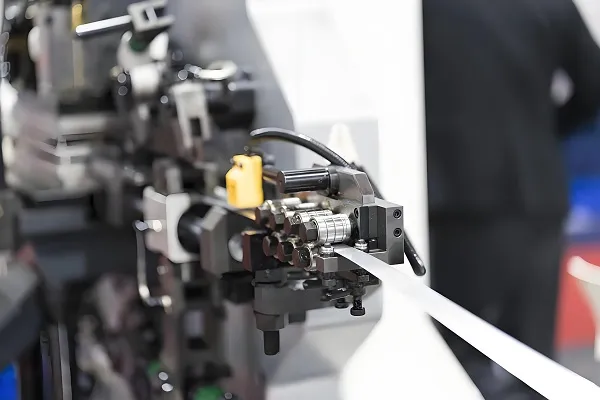

Cutting processing: including wire cutting, electrical discharge machining and laser cutting, these methods can achieve high precision parts cutting.

Milling processing: cutting materials by rotating tools, suitable for processing planes, curves and complex shapes of small parts.

Turning: performed on precision lathes, used for machining rotary parts such as cylindrical, conical or spherical.

Grinding and polishing: Used to improve the surface finish and accuracy of parts.

Heat treatment: such as carburizing, quenching, tempering and other special treatments to enhance the mechanical properties and wear resistance of the material.

In addition, with the development of technology, more and more precision-machined small parts are machined using Computer Numerical Control (CNC) technology to achieve higher machining accuracy and efficiency.CNC technology allows special designs to be programmed to be converted into precise shapes, which greatly improves productivity and product quality.