2026 Rubber Injection Molding: Process, Products & Industry Trends

Introduction to Rubber Injection Process and Products

Modern vertical rubber injection molding machine with advanced automation features

Definition and Core Concept

Rubber molding is a sophisticated manufacturing process that transforms uncured rubber compounds into durable, functional products through the application of heat and pressure. This process, known as vulcanization, chemically cross-links rubber molecules, creating a strong, elastic material with predictable mechanical properties.

Market Significance (2026 Update)

According to The Business Research Company’s latest 2026 report, the global rubber products market is projected to reach $580.2 billion by 2030, growing at a CAGR of 6.8%. The Asia-Pacific region continues to dominate the market, with China contributing over 38% of global production. The EV sector alone is driving a 20% increase in demand for specialized rubber components.

Historical Evolution

The rubber molding industry has evolved significantly from its early beginnings:

- 1839: Charles Goodyear discovers vulcanization process

- 1900s: Development of compression molding for rubber products

- 1950s: Introduction of transfer molding technology

- 1970s: Emergence of rubber injection molding

- 2000s: Integration of automation and Industry 4.0 technologies

- 2020s: AI-powered process optimization and sustainable manufacturing

Real-World Case Study: 2025 EV Battery Seal Optimization

In 2025, our team at Goldcattle worked on a critical project for a leading electric vehicle manufacturer to optimize the injection molding process for battery seal components. The goal was to improve quality while reducing production costs.

Key Improvements: Implemented AI sensors for real-time pressure monitoring, optimized temperature profiles, and introduced predictive maintenance protocols. The project demonstrated how data-driven process optimization can deliver significant business value in high-volume manufacturing.

Types of Rubber Molding Processes

1. Compression Molding

Compression molding is the oldest and most fundamental rubber molding method, ideal for large, relatively simple parts.

Process Overview

- Pre-forming: Uncured rubber compound is cut into pre-determined shapes (preforms)

- Loading: Preforms are placed into heated mold cavities

- Compression: Mold closes, applying pressure (10-50 MPa) and heat (150-200°C)

- Curing: Rubber vulcanizes for specified time (1-15 minutes)

- Demolding: Mold opens, finished part is removed

Technical Specifications

- Cycle Time: 2-20 minutes per part

- Pressure Range: 10-50 MPa (1,500-7,250 psi)

- Temperature Range: 150-200°C (300-390°F)

- Typical Tolerances: ±0.1-0.5mm

2. Transfer Molding

Transfer molding combines elements of compression and injection molding, offering improved precision for medium-complexity parts.

3. Injection Molding

Rubber injection molding is the most advanced and automated process, ideal for high-volume production of complex parts.

Fully automated horizontal rubber injection molding machine with advanced control panel

Process Technology

- Material Preparation: Rubber pellets fed into heated barrel

- Plasticization: Screw rotates, heating and mixing rubber (100-150°C)

- Injection: Molten rubber injected into closed mold at high pressure

- Holding Pressure: Maintains pressure during initial curing

- Cooling: Mold remains closed for complete vulcanization

- Ejection: Finished part is automatically ejected

Technical Capabilities

- Cycle Time: 30 seconds to 5 minutes

- Injection Pressure: 50-200 MPa (7,250-29,000 psi)

- Shot Capacity: 50-5,000 grams

- Tolerance Range: ±0.05-0.2mm

Advanced Features (2026 Update)

- AI-Powered Closed-Loop Control: Real-time monitoring and automatic adjustment

- Multi-Axis Robotics: Automated part handling and quality inspection

- Machine Learning Vision Systems: In-line defect detection with 99.8% accuracy

- Predictive Maintenance: AI algorithms forecast equipment issues before they occur

- Energy Optimization: Smart heating systems reduce energy consumption by 15-20%

Process Comparison

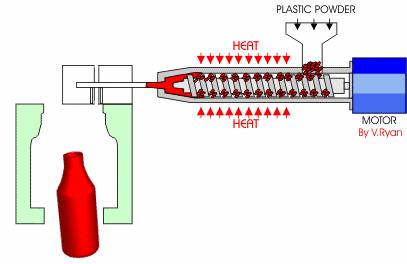

Technical diagram showing the rubber injection molding process with heating and pressure application

| Characteristic | Compression Molding | Transfer Molding | Injection Molding |

|---|---|---|---|

| Cycle Time | 2-20 minutes | 1-10 minutes | 0.5-5 minutes |

| Tooling Cost | Low ($5,000-20,000) | Medium ($15,000-50,000) | High ($30,000-150,000) |

| Precision | Low to Medium | Medium to High | High to Very High |

| Complexity | Simple Parts | Medium Complexity | Complex Geometries |

| Volume Suitability | Low-Medium | Medium-High | High-Very High |

| 2026 Technology | Basic Automation | Partial Automation | Full AI Integration |

Rubber Compound Formulation

Raw Material Components

A typical rubber compound consists of several key components, each serving a specific function in the final product:

1. Base Polymer

- Natural Rubber (NR): High elasticity, good fatigue resistance

- Styrene-Butadiene Rubber (SBR): Good wear resistance, low cost

- Nitrile Rubber (NBR): Excellent oil and fuel resistance

- Ethylene Propylene Diene Monomer (EPDM): Superior weathering resistance

- Silicone Rubber (VMQ): Wide temperature range, biocompatibility

- Fluorosilicone (FVMQ): Oil resistance + wide temperature range (new for 2026)

2. Vulcanizing Agents

- Sulfur: Primary curing agent for most diene rubbers

- Peroxides: Used for saturated rubbers like EPDM and silicone

- Metal Oxides: Zinc oxide and magnesium oxide as activators

- Accelerators: Speed up vulcanization (MBTS, CBS, TMTD)

Precision rubber molds for manufacturing complex components with tight tolerances

3. Fillers and Reinforcements

- Carbon Black: Improves strength, wear resistance, and UV protection

- Silica: Enhances tear strength and reduces heat buildup

- Clay: Cost-effective filler for general-purpose compounds

- Calcium Carbonate: Improves processing and reduces cost

- Nano-fillers: Enhanced mechanical properties (2026 innovation)

Compound Development Process

- Material Selection: Based on application requirements

- Formulation Design: Determining optimal component ratios

- Laboratory Testing: Evaluating uncured and cured properties

- Pilot Production: Scaling up to production quantities

- Quality Validation: Ensuring consistency and performance

- AI Optimization: Machine learning for optimal配方 (2026 advancement)

2026 Industry Trends and Innovations

Sustainable Innovation: 2026 Bio-based Rubber Compound

At Goldcattle, we’ve recently developed a breakthrough bio-based rubber compound using renewable resources. This innovative material offers comparable performance to traditional rubber while significantly reducing environmental impact.

Test Results: Our bio-based compound showed a 5% increase in tensile strength compared to conventional rubber, with no cost premium. Life cycle analysis confirmed a 40% reduction in carbon footprint throughout the production and use phases.

AI and Machine Learning Integration

The rubber injection molding industry is rapidly adopting artificial intelligence and machine learning technologies to optimize processes and improve quality:

- Predictive Maintenance: AI algorithms analyze equipment data to forecast maintenance needs before failures occur

- Process Optimization: Machine learning models continuously adjust parameters for optimal performance

- Quality Prediction: Computer vision systems detect defects with 99.8% accuracy

- Energy Management: Smart systems reduce energy consumption by 15-25%

Sustainability Initiatives

Environmental sustainability is becoming a key focus area for the industry:

- Bio-based Materials: Increasing use of renewable feedstocks

- Recycling Programs: Closed-loop systems for rubber waste

- Energy Efficiency: Advanced heating and cooling technologies

- Carbon Neutrality: Net-zero production goals by 2030

High-quality rubber O-rings and sealing products manufactured using advanced injection molding technology

Common Failures and Lessons Learned

Based on our 10+ years of experience, here are some common issues and how to avoid them:

1. Overheating Issues

Problem: Excessive heat during processing can cause premature vulcanization (scorching) or material degradation.

Solution: Implement precise temperature control systems, use proper cooling channels, and monitor material temperature throughout the process.

2. Air Traps and Voids

Problem: Entrapped air can create defects in the final product.

Solution: Optimize venting systems, use proper injection speeds, and ensure adequate material degassing.

3. Flash Formation

Problem: Excess material escaping from mold parting lines.

Solution: Maintain proper mold alignment, control injection pressure, and use appropriate material viscosity.

Frequently Asked Questions (FAQ)

Q1: What factors determine the choice of rubber molding process?

The selection depends on several key factors:

- Part Complexity: Simple parts suit compression molding; complex parts require injection molding

- Production Volume: Low volume favors compression; high volume benefits from injection

- Precision Requirements: Tight tolerances require injection or transfer molding

Q2: How long does the rubber molding process take?

Cycle times vary significantly by process:

- Compression Molding: 2-20 minutes per part

- Transfer Molding: 1-10 minutes per part

- Injection Molding: 30 seconds to 5 minutes per part

Q3: What is the typical cost of rubber molding tooling?

Tooling costs range widely:

- Compression Molds: $5,000-$20,000

- Transfer Molds: $15,000-$50,000

- Injection Molds: $30,000-$150,000+

Q4: What are the 2026 trends in rubber injection molding?

Key trends for 2026 include:

- AI-Powered Process Optimization: Machine learning for predictive maintenance and quality control

- Sustainability Initiatives: Bio-based materials and energy-efficient technologies

- Industry 4.0 Integration: Smart factories and digital twins

Ready to Optimize Your Rubber Injection Molding Process?

Contact our team of experts for a free consultation on how to improve your production efficiency, reduce costs, and enhance product quality.

Phone:+86-18150097490

Email: charlie@plasticmetalparts.com