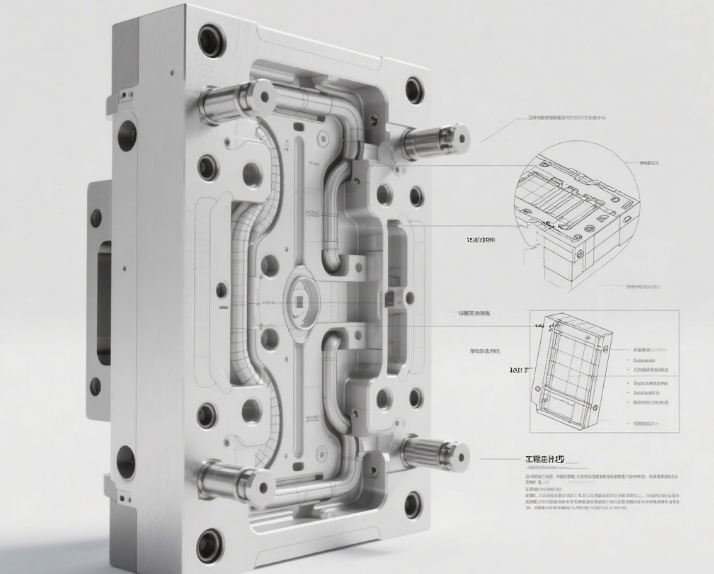

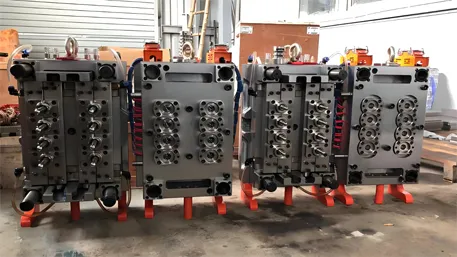

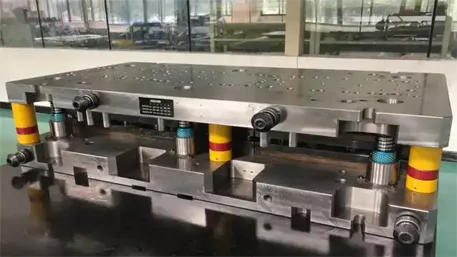

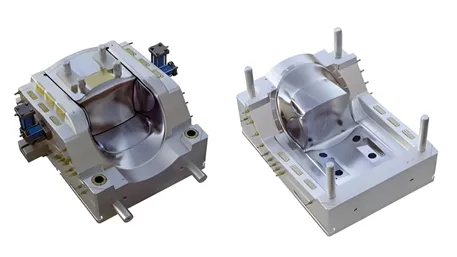

Xiamen Goldcattle: 26 – year injection mold manufacturing

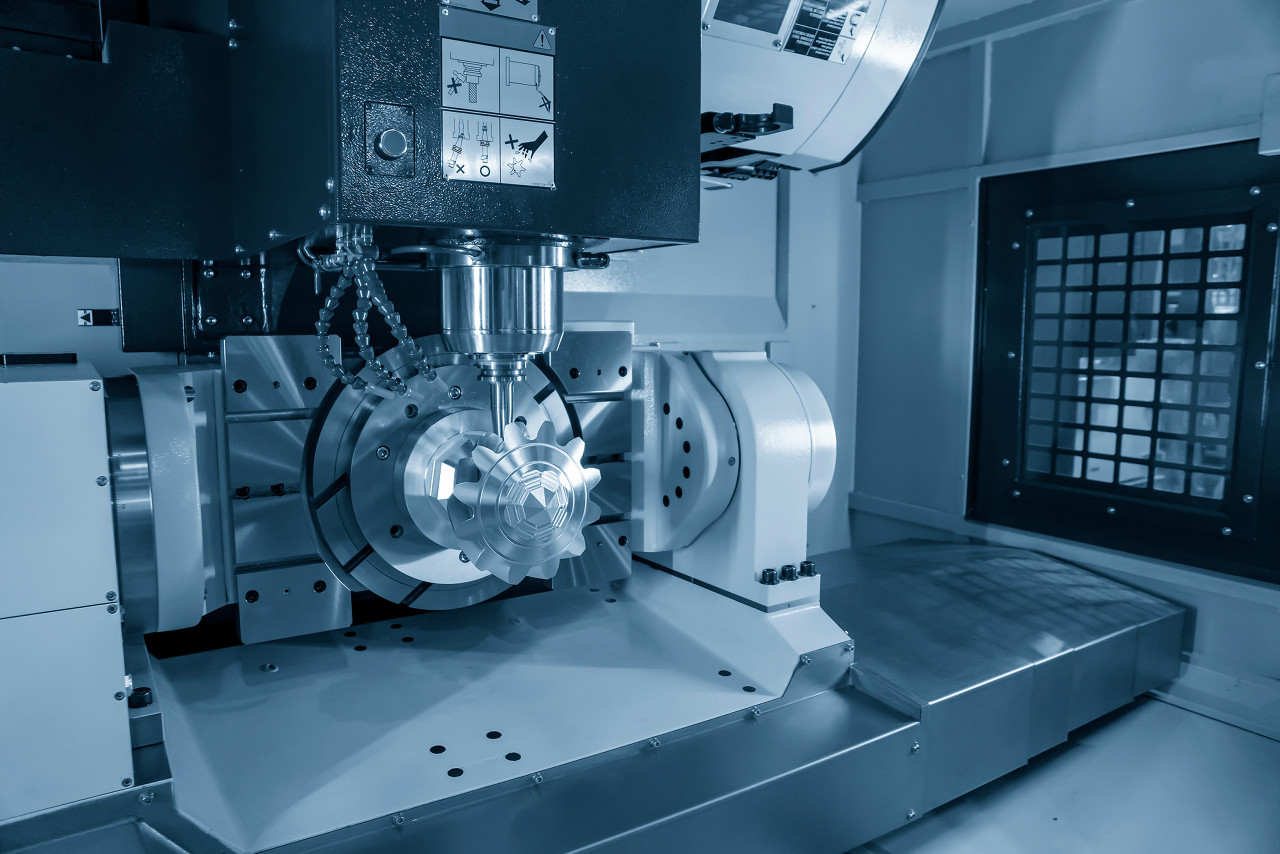

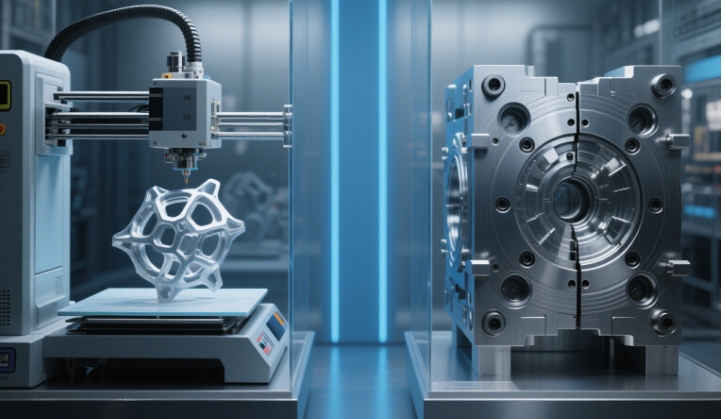

As a national high – tech enterprise, Xiamen Goldcattle Industrial & Trading Co., Ltd. (official website: https://www.xmgoldcattle.com/) has become a trusted injection mold customization expert for global customers with its…