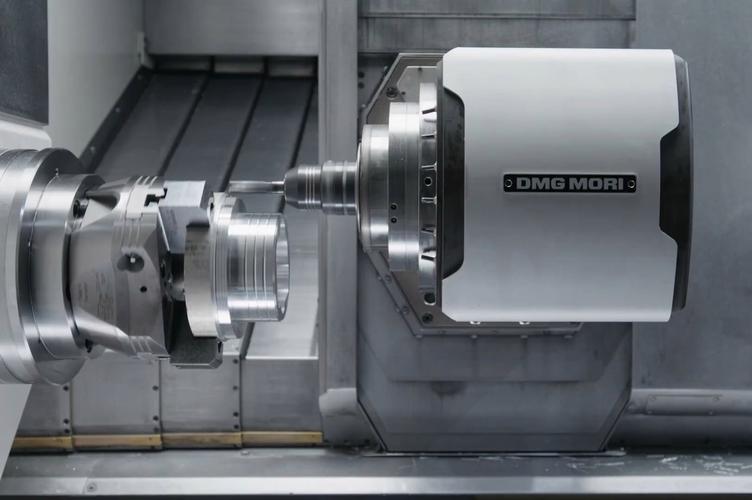

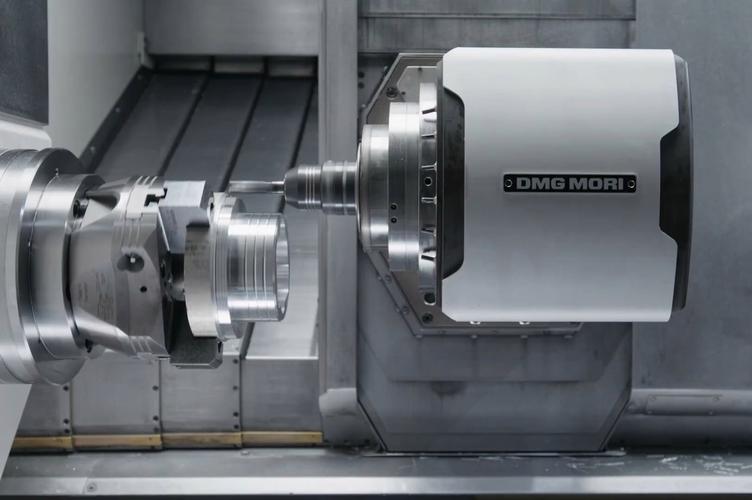

What Is a CNC Turning Center?

A CNC turning center is a computer-controlled machine tool built to shape rotational or cylindrical parts—think shafts, bolts, or bearing sleeves. Unlike manual lathes (where a worker guides tools by hand), it uses preprogrammed G/M codes to automate cutting: the workpiece spins (via a spindle), and stationary tools remove material with consistent precision (often ±0.005mm tolerance). It’s the backbone of mass-producing parts that need uniform size and smooth surfaces.

How It Works (In 3 Simple Steps)

- Load & Secure: Clamp raw material (e.g., a steel bar) into a chuck—the machine’s “grip” that spins the workpiece.

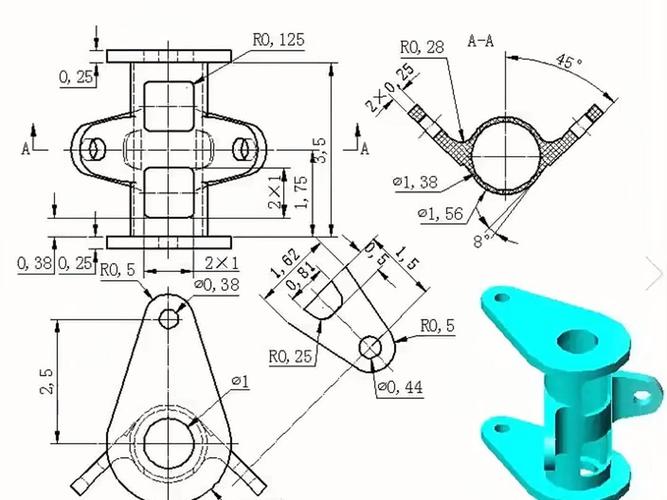

- Program the Toolpath: Use CAD/CAM software to set cuts, speeds, and tool changes (e.g., “turn a φ15mm shaft, then drill a 4mm hole at the end”).

- Auto-Machine: The center runs the program: the spindle spins the workpiece, a tool turret swaps cutting tools automatically, and the finished part is released—no manual adjustments needed.

Key Parts That Matter

- Spindle: The motor that spins the workpiece (faster speeds work for soft metals like aluminum; slower for tough steel).

- Tool Turret: Holds 8–12 tools (drills, lathe blades) and swaps them in <1 second—critical for multi-step parts.

- CNC Controller: The “brain” (often FANUC or SIEMENS) that executes code and alerts you to issues (e.g., dull tools or loose chucks).

What It Makes (Common Applications)

Nearly any part that needs a cylindrical shape:

- Automotive: Engine crankshafts, bolt heads, or gear hubs.

- Industrial: Pump housings, threaded rods, or bearing sleeves.

- Medical: Tiny titanium pins for implants (its precision avoids tissue irritation).

Why It Beats Manual Lathes

For repeatable work, it’s no contest:

- Precision: Manual lathes depend on skill (±0.1mm tolerance); CNC hits ±0.005mm.

- Speed: It makes 5x more parts—e.g., 200 shafts/hour vs. 40 manually.

- Automation: Run it 24/7 with minimal supervision; manual lathes need constant operator input.

A Craftsman’s Quick Tip

If your parts vibrate (causing rough surfaces), fix it fast: Use a “live center” (a support for the workpiece’s far end) for long, thin parts (like a 100mm-long φ5mm shaft). I once saved a batch of aluminum shafts by adding one—vibration stopped, and surfaces turned smooth.

Final Thought

A CNC turning center isn’t just a “better lathe”—it’s a workhorse for consistent, fast rotational parts. For anyone making more than 10 of the same cylindrical part, it cuts time, reduces scrap, and keeps quality steady.