Answer

“Custom parts” refer to non-standard components designed and manufactured according to specific user requirements, application scenarios, or technical specifications, meeting personalized needs in dimensions, shapes, functions, or materials, as opposed to mass-produced standard parts.

Extended Response

I. Core Definition and Essential Characteristics of Custom Parts

1. Fundamental Difference from Standard Parts

- Standard parts: Mass-produced per unified specifications (e.g., ISO, GB standards), such as bolts and bearings, suitable for general applications;

- Custom parts: Originating from unique user scenarios, such as special-shaped connectors in aerospace or personalized implants in medical devices, requiring “one-to-one” development.

2. Core Features

- Requirement-driven: Based on explicit technical parameters (e.g., tolerance ±0.01mm), installation space constraints (e.g., micro-parts with diameter ≤5mm), or special functional needs (e.g., seals resistant to 300℃);

- Non-mass production: Typically produced in quantities from 1 to hundreds, rarely in large scales;

- Technical customization: May involve material modification (e.g., titanium alloy surface plating) or structural innovation (e.g., topologically optimized lightweight brackets).

II. Typical Application Fields and Scenarios of Custom Parts

1. High-End Manufacturing

- Aerospace:

- Case: Turbine blades for aircraft engines require custom nickel-based superalloys with complex cooling channel designs to withstand creep at 1200℃;

- Requirement features: High reliability (failure probability <10^-6) and strict weight limits (error ≤0.1g).

- Medical devices:

- Case: 3D-printed titanium skull repair plates, customized for arc and aperture based on patient CT data to adapt to bone cell growth;

- Requirement features: Biocompatibility (complying with ISO 10993) and personalized adaptation (error ≤0.5mm).

2. Special Equipment and Research Fields

- New energy equipment:

- Case: Support components for superconducting magnets in nuclear fusion devices, requiring custom high-purity oxygen-free copper to maintain mechanical properties at -269℃;

- Scientific instruments:

- Case: Vacuum chamber parts for particle colliders, made of custom stainless steel with surface roughness Ra<0.2μm to avoid particle scattering.

3. Consumer Goods and Personalized Scenarios

- Automotive modification:

- Case: Custom carbon fiber aerodynamic components for racing cars, such as rear wing brackets designed for angle and strength based on vehicle wind tunnel data;

- Cultural creativity and luxury goods:

- Case: Custom precious metal accessory parts, achieving micron-level patterns via CNC engraving to match brand-exclusive design languages.

III. Full-Process Development Logic of Custom Parts

1. Requirement Analysis and Technical Definition

- Key steps:

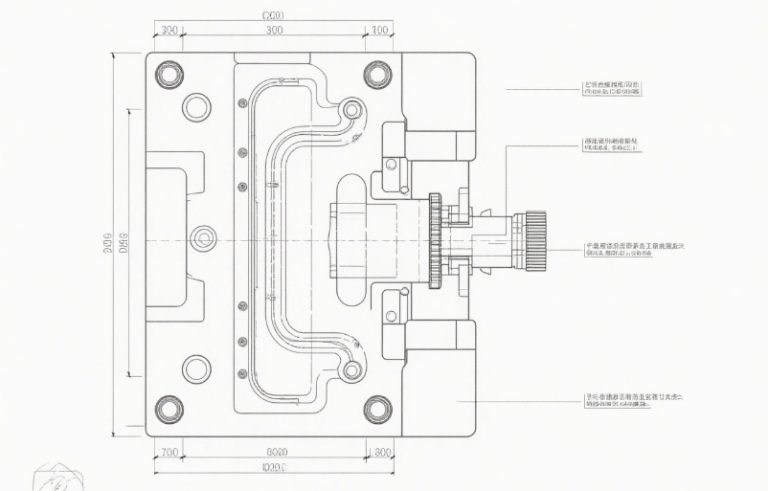

- Clients provide technical drawings (e.g., CAD models) or scenario descriptions (e.g., “sensor housing pressure resistance at 1000m deep sea”);

- Engineers convert them into quantifiable indicators: material (titanium alloy TC4), dimensional tolerance (±0.03mm), surface treatment (anodizing).

2. Design and Simulation Validation

- Tool applications:

- CAD design: Use SolidWorks to draw 3D models, such as precise calculation of tooth parameters for special-shaped gears;

- CAE simulation: Simulate part stress via ANSYS, such as deformation of rocket engine nozzles under high pressure, to avoid design flaws.

3. Manufacturing Process Selection

- Typical process comparison:

Process Type Applicable Scenarios Precision Range Cost Characteristics CNC machining Metal structures (e.g., aluminum casings) ±0.01-0.1mm Economical for medium batches 3D printing (SLM) Complex hollow structures (e.g., heat sinks) ±0.05-0.2mm Fast prototyping for low batches Precision casting Complex curved parts (e.g., impellers) ±0.1-0.5mm Low cost for batches Electrical Discharge Machining (EDM) Micro-hole machining on hard materials (e.g., tungsten steel molds) ±0.005mm High cost for single parts

4. Quality Control and Delivery

- Inspection methods:

- Coordinate Measuring Machine (CMM) for complex surface profile detection;

- Nondestructive Testing (UT/RT) for internal defect check in castings;

- Delivery documents: Accompanied by material reports, inspection records (e.g., hardness test HRC 35-40), and performance test reports.

IV. Core Advantages and Practical Challenges of Custom Parts

1. Core Advantages

- Functional adaptability: Solves scenarios unmet by standard parts, such as non-standard bushings for robot joints requiring both high stiffness and low friction;

- Innovation driving force: Promotes technological breakthroughs, e.g., custom ceramic parts for semiconductor equipment meeting ultra-clean environment requirements (particle contamination <10 pieces/ft³);

- Supply chain flexibility: Meets urgent needs, such as custom spare parts for aerospace missions, shortened to 48-hour delivery via rapid prototyping.

2. Practical Challenges

- Cost pressure:

- High single-piece R&D costs (e.g., mold opening fees accounting for 40% of total cost), making unit prices 5-10 times higher than standard parts for low batches;

- Long delivery cycles:

- Complex parts require multi-process iteration (e.g., 5-7 clampings for precision grinding), with conventional cycles of 2-4 weeks, far exceeding standard parts’ off-the-shelf supply;

- High technical threshold:

- Requires cross-disciplinary knowledge (e.g., materials science + mechanics + manufacturing processes), with SMEs often relying on external technical support (e.g., entrusted R&D by research institutes).

V. Industry Trends and Technological Innovations in Custom Parts

1. Digital-Driven Custom Efficiency

- Parametric design: Establish design templates via software like PTC Creo, automatically generating models upon user input of key parameters (e.g., diameter, length), shortening design time by 50%;

- Smart manufacturing collaboration: Cloud platforms (e.g., Alibaba 1688 custom zone) enable digitalized full processes from requirement release to process quotation and production tracking. Case: A car parts factory reduced custom response time from 72 to 8 hours via cloud platforms.

2. New Material and Process Breakthroughs

- Metal Matrix Composites (MMC): Custom parts like aluminum-silicon carbide (Al-SiC) for 5G base station heat sinks, with thermal conductivity reaching 180W/m·K to meet high-power density needs;

- Hybrid manufacturing processes: Combining CNC and 3D printing, e.g., printing titanium alloy frames first, then milling for surface precision Ra0.8μm.

3. Business Model Innovations

- Customization on Demand (C2M): Typical in medical devices, a company provides 24-hour delivery of custom implants via integrated “scan-design-print” services for orthopedic hospitals;

- Modular customization: Disassembling parts into standard + custom modules, e.g., robot arm joint components with standard bases and custom end fixtures, reducing costs by 30%.

Extended Supplement: Cost Control Strategies for Custom Parts

- Design for Manufacturability (DFM): Optimize structures during design to avoid special processes (e.g., replacing blind holes with depth >5x diameter with through holes);

- Batch optimization: Consolidate similar demands for unified production, e.g., scheduling 10 clients’ similar parts together to reduce mold cost allocation;

- Alternative material selection: Replace titanium alloy with high-strength plastic (PEEK) for 60% cost reduction in non-critical load-bearing parts.

From key components of space rockets to personalized daily products, custom parts build a unique value chain in areas beyond standard parts, relying on comprehensive upgrades in design tools, manufacturing processes, and supply chain collaboration.