The minimum bend radius (MBR) for sheet metal is the smallest inner radius achievable during bending without causing material cracking, tearing, or excessive deformation. It depends on material ductility, thickness, hardness, and grain direction, typically ranging from 0.5× to 3× the material thickness for common metals like aluminum and steel. Proper MBR ensures structural integrity and avoids post-bend failures in fabricated parts.

Detailed Analysis of Minimum Bend Radius in Sheet Metal

1. Technical Definition & Key Influencing Factors

The minimum bend radius is defined as the smallest radius of the inner curve formed when sheet metal is bent, determined by the material’s ability to stretch without fracturing. Several technical factors govern this limit:

- Material Ductility: Ductile materials (e.g., aluminum 3003, low-carbon steel) tolerate smaller radii due to their ability to deform plastically. Brittle materials (e.g., high-carbon steel, cold-rolled stainless steel) require larger radii to avoid cracking. For example, 1100 aluminum (high ductility) has an MBR of ~0.5× thickness, while 410 stainless steel (higher hardness) needs ~1.5× thickness.

- Material Thickness (T): Thicker sheets require larger MBRs. As thickness increases, the outer fibers of the bend experience greater 拉伸 stress; a 1mm thick sheet may bend to 0.5mm radius, but a 5mm sheet of the same material might need a 2.5mm radius to prevent tearing.

- Hardness & Heat Treatment: Work-hardened materials (e.g., cold-rolled steel) have higher hardness and lower ductility, increasing MBR. Annealed materials (heat-treated to reduce hardness) regain ductility, allowing smaller radii. For instance, annealed 304 stainless steel has an MBR of 1×T, vs. 2×T for cold-rolled 304.

- Grain Direction: Sheet metal’s rolled grain structure creates anisotropy—bending parallel to the grain (along rolling direction) requires a larger MBR than bending perpendicular to the grain. A 2mm mild steel sheet bent parallel to grain may need 1×T, but only 0.5×T when bent perpendicularly.

2. Calculation & Process Guidelines

Determining MBR involves empirical formulas and material-specific data, integrated into bending process planning:

- General Formula: MBR is often expressed as a multiple of sheet thickness (T):

- Ductile metals: MBR = 0.5×T to 1×T (e.g., aluminum 6061, mild steel).

- Semi-ductile metals: MBR = 1×T to 2×T (e.g., 304 stainless steel, brass).

- Low-ductility metals: MBR = 2×T to 3×T (e.g., high-carbon steel, titanium).

- Bend Allowance Consideration: The MBR must account for bend allowance—the length of material consumed in the bend. A smaller radius increases stretch in the outer fibers; exceeding the material’s tensile limit causes cracking.

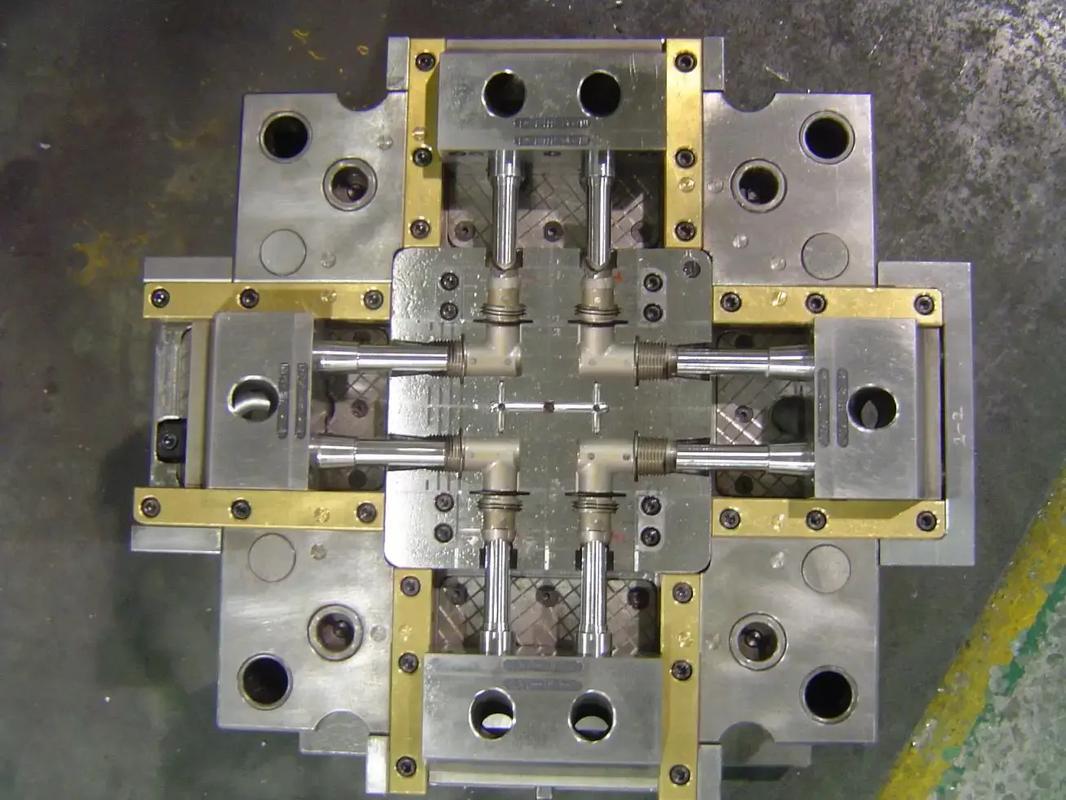

- Tooling Alignment: The die radius in press brakes should match or slightly exceed the MBR. Using a die radius smaller than MBR forces excessive deformation, while a larger radius ensures smooth material flow but may increase springback.

3. Material-Specific Minimum Bend Radii

Different sheet metals have distinct MBRs based on their mechanical properties:

-

Aluminum Alloys:

- 1100 (pure aluminum, highly ductile): MBR = 0.25×T to 0.5×T, ideal for decorative bends in signage or consumer goods.

- 6061 (heat-treatable, medium strength): MBR = 0.5×T to 1×T, used in automotive brackets and structural parts.

- 7075 (high strength, lower ductility): MBR = 1.5×T to 2×T, common in aerospace components where strength prioritizes over bendability.

-

Steels:

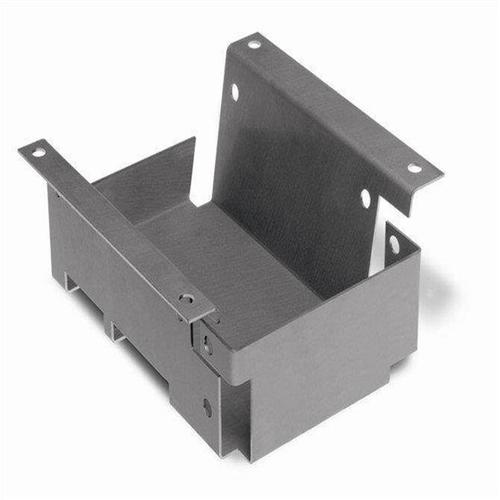

- Mild Steel (A36, low carbon): MBR = 0.5×T to 1×T, versatile for construction, automotive panels, and enclosures.

- Cold-Rolled Steel (CRS): Work-hardened, so MBR = 1×T to 1.5×T, used in precision parts like electrical boxes.

- Stainless Steel 304: MBR = 1×T (annealed) to 2×T (cold-rolled), critical for corrosion-resistant parts in food processing or marine applications.

-

Specialty Metals:

- Copper & Brass: High ductility allows MBR = 0.5×T, used in plumbing fittings and electrical components.

- Titanium (Ti-6Al-4V): Low ductility requires MBR = 3×T to 5×T, necessary for aerospace and medical parts where strength and biocompatibility are key.

4. Product & Application Requirements

MBR directly impacts part functionality, durability, and manufacturing feasibility across industries:

- Structural Parts: Brackets, frames, and supports often require larger MBRs (1×T to 2×T) to distribute stress, preventing fatigue failure under load. For example, automotive chassis brackets use MBR = 1.5×T to withstand vibration.

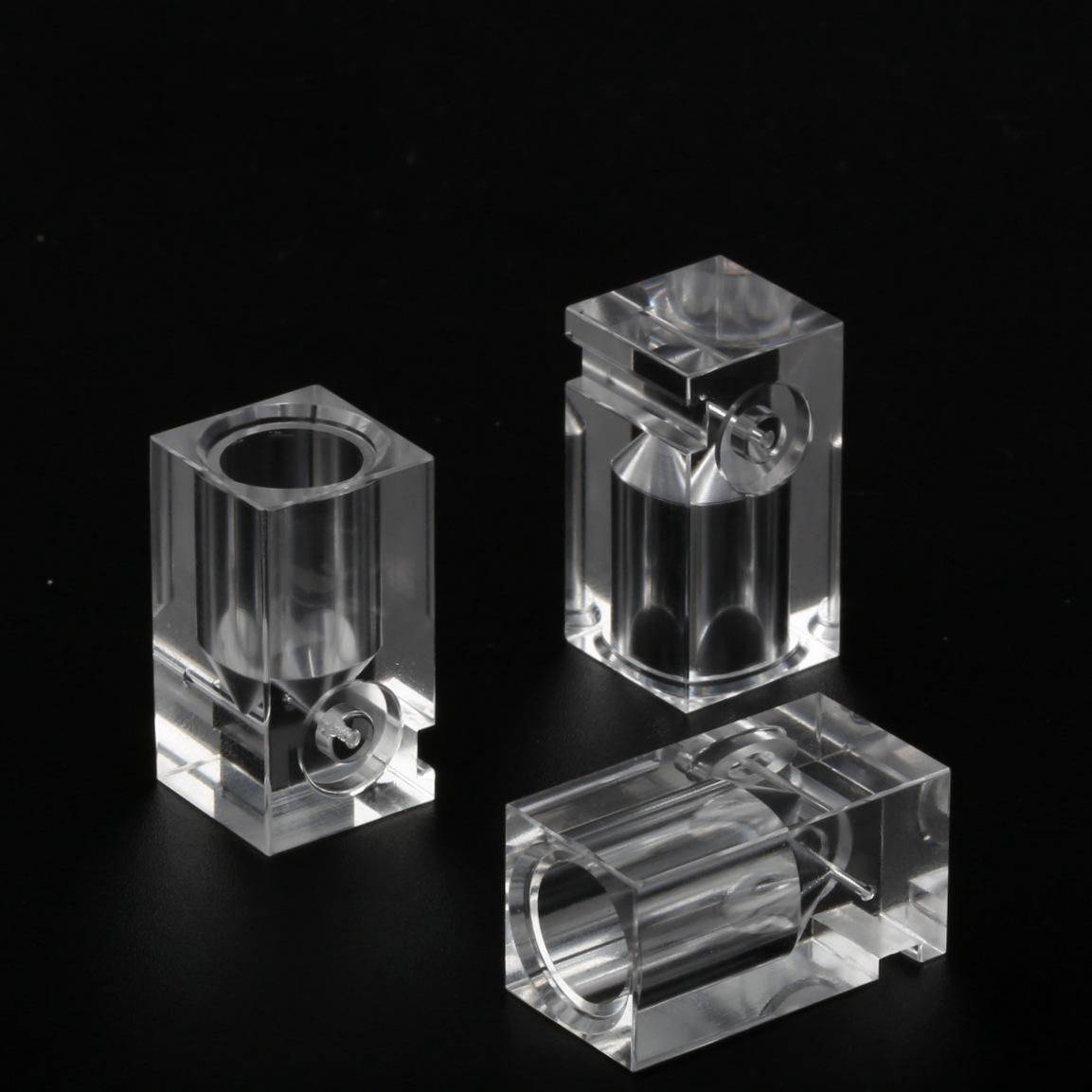

- Precision & Enclosure Parts: Electronic enclosures or small components need smaller MBRs (0.5×T) to fit tight spaces. A 1mm thick aluminum laptop chassis might use MBR = 0.5mm for sleek, compact design.

- Aerospace & Defense: Parts like aircraft skins or missile casings use MBR = 2×T to 3×T (for titanium or high-strength steel) to ensure integrity under extreme pressure and temperature.

- Decorative & Consumer Goods: Signage, furniture, or appliances prioritize aesthetics, using MBR = 0.5×T (aluminum or brass) for smooth, visually appealing bends without cracks or creases.

5. Challenges & Mitigation Strategies

Incorrect MBR selection leads to defects; addressing these requires process adjustments:

-

Cracking in Bends: Caused by MBR smaller than material limits. Solutions include:

- Annealing the material to increase ductility (e.g., annealing cold-rolled steel at 600°C for 1 hour).

- Increasing MBR to match material capabilities (e.g., switching from 0.5×T to 1×T for 304 stainless steel).

- Using lubricants during bending to reduce friction and stress on outer fibers.

-

Excessive Springback: Larger MBRs can increase springback (elastic recovery), altering final dimensions. Mitigations:

- Over-bending the part (e.g., bending to 95° for a desired 90° angle) to compensate for springback.

- Using bottoming dies to force material into the die cavity, reducing residual stress.

-

Thickness-Related Issues: Thick sheets (>3mm) risk outer fiber tearing. Strategies:

- Using incremental bending (multiple small bends instead of one sharp bend).

- Selecting ductile alloys (e.g., switching from 410 stainless to 304 stainless for thicker parts).

6. Industry Standards & Best Practices

Adhering to standards ensures consistent MBR performance:

- ASTM & ISO Guidelines: ASTM B366 (for copper) and ISO 15745 (sheet metal bending) provide MBR recommendations based on material and thickness.

- Design for Manufacturability (DFM): Engineers specify MBR early in design, avoiding unfeasible small radii. For example, a 2mm thick 6061 aluminum part should specify MBR ≥1mm to ensure manufacturability.

- Testing & Validation: Prototyping with different radii (e.g., 0.5×T, 1×T, 1.5×T) identifies the smallest crack-free radius for each material-thickness combination, critical for high-volume production.

By aligning MBR with material properties, process capabilities, and application needs, manufacturers ensure sheet metal parts bend without defects, balancing functionality, durability, and cost-effectiveness across industries.