Table of Contents

- The Revolutionary Significance of 3D Printing

- Xiamen Goldcattle’s 3D Printing Capabilities

- 3D Printing Technology Principles

- Diversified 3D Printing Applications

- Material Selection and Characteristics

- Technical Advantages and Features

- Service Process and Cases

- Why Choose Xiamen Goldcattle

The Revolutionary Significance of 3D Printing

In today’s rapidly developing manufacturing industry, 3D printing technology is changing traditional production methods with its unique advantages. This technology, known as “additive manufacturing,” can directly transform digital models into physical products, providing unlimited possibilities for innovative design and personalized manufacturing.

From conceptual models to functional parts, from artworks to industrial components, 3D printing is playing an increasingly important role in various fields. And Xiamen Goldcattle Factory is an active practitioner and innovator in this technical field.

Xiamen Goldcattle’s 3D Printing Capabilities

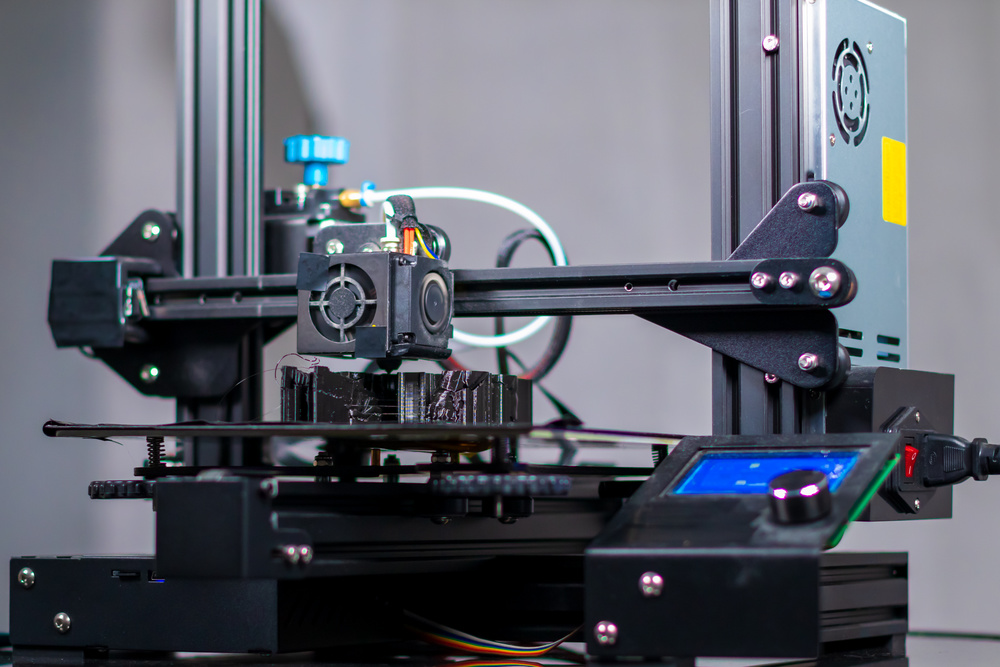

As a national high-tech enterprise with 26 years of manufacturing experience, Xiamen Goldcattle Factory has keenly grasped the development trend of 3D printing technology and established a complete 3D printing service system.

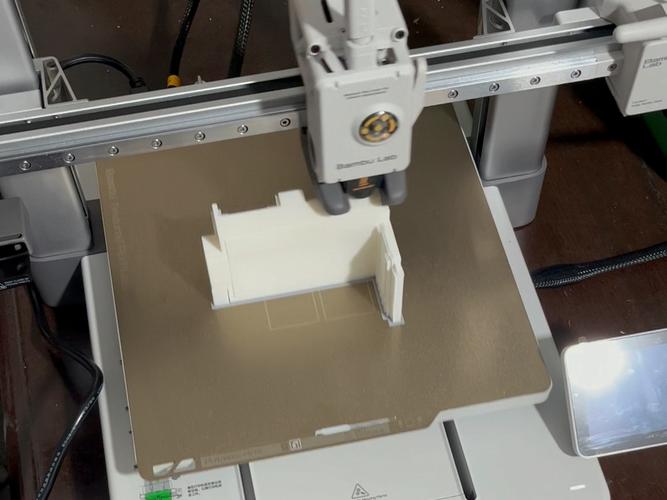

Walking into Xiamen Goldcattle’s 3D printing workshop, you will see multiple advanced 3D printers working in an orderly manner. These devices can handle multiple materials and produce high-precision, complex products, providing customers with comprehensive services from prototype production to small-batch manufacturing.

3D Printing Technology Principles

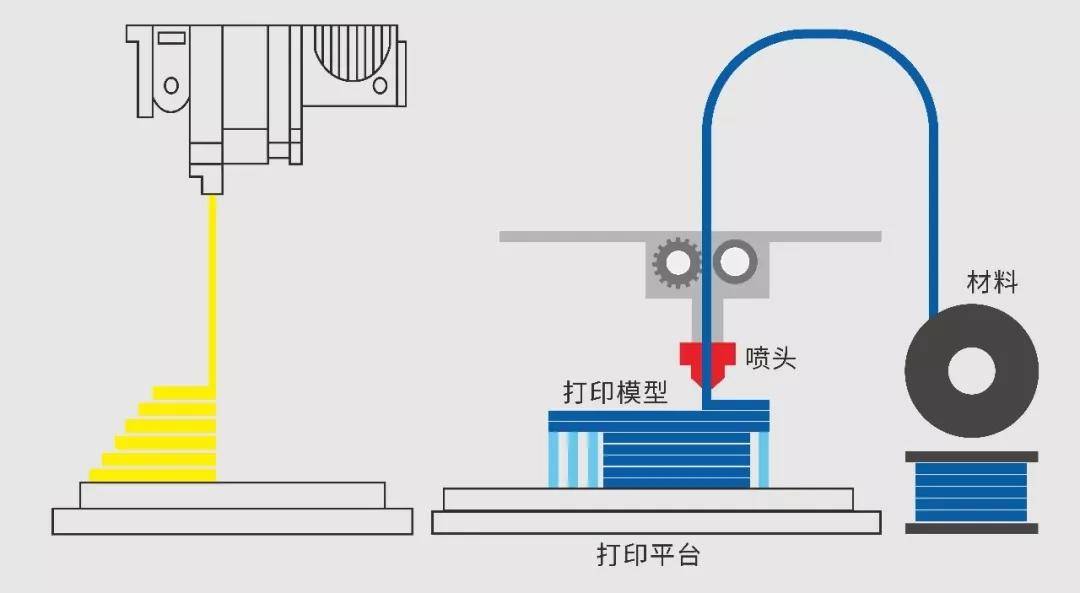

3D printing technology seems magical, but its principle is not complicated. Simply put, it manufactures three-dimensional objects by layer-by-layer material accumulation:

1. Digital Modeling

First, designers use CAD software to create three-dimensional digital models of products. This model contains all the detailed and dimensional information of the product.

2. Slicing Processing

The 3D model is divided into countless thin layers, each with a thickness usually around 0.1mm. This step is like slicing bread into countless pieces.

3. Path Planning

The computer generates printing paths for each layer, determining the movement trajectory of the nozzle and the material accumulation method.

4. Layer-by-Layer Printing

The 3D printer accumulates materials layer by layer according to the planned path. After each layer is printed, the workbench descends a distance equal to the layer thickness, then starts printing the next layer.

5. Post-processing

After printing is completed, necessary post-processing is performed on the product, such as removing support structures, sanding and polishing, to meet the final quality requirements.

Diversified 3D Printing Applications

Xiamen Goldcattle Factory’s 3D printing services cover multiple fields and can meet the needs of different customers:

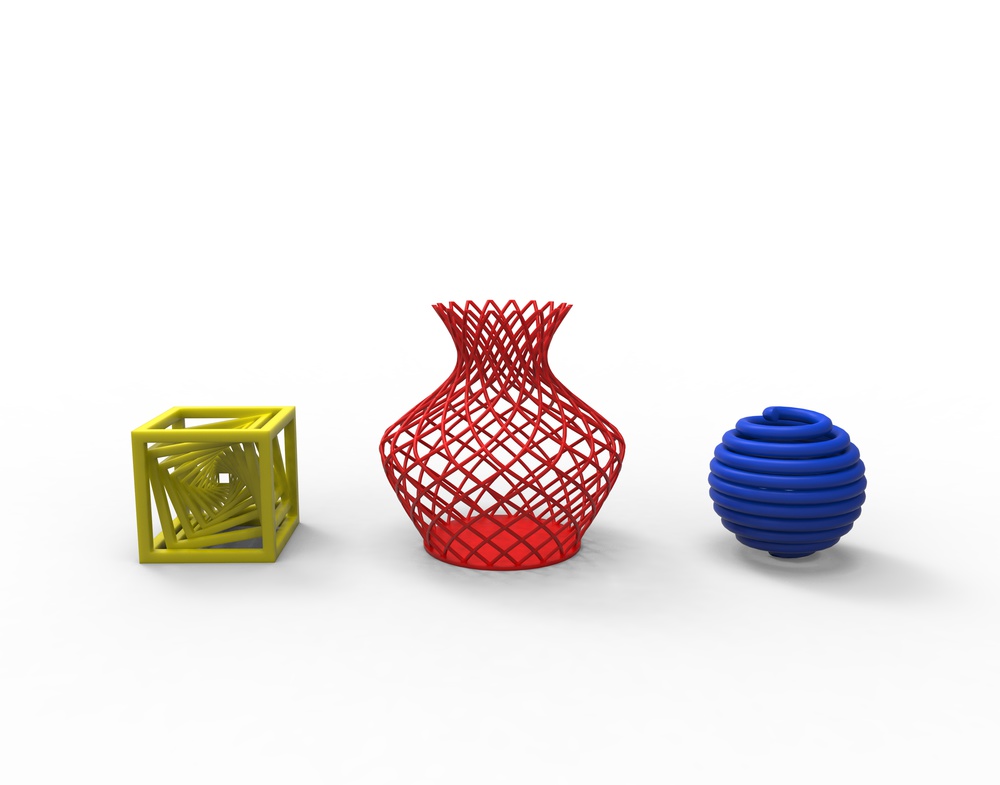

3D Printing Models

Quickly produce product prototypes for design verification, functional testing, and marketing display. This greatly shortens the product development cycle and reduces development costs.

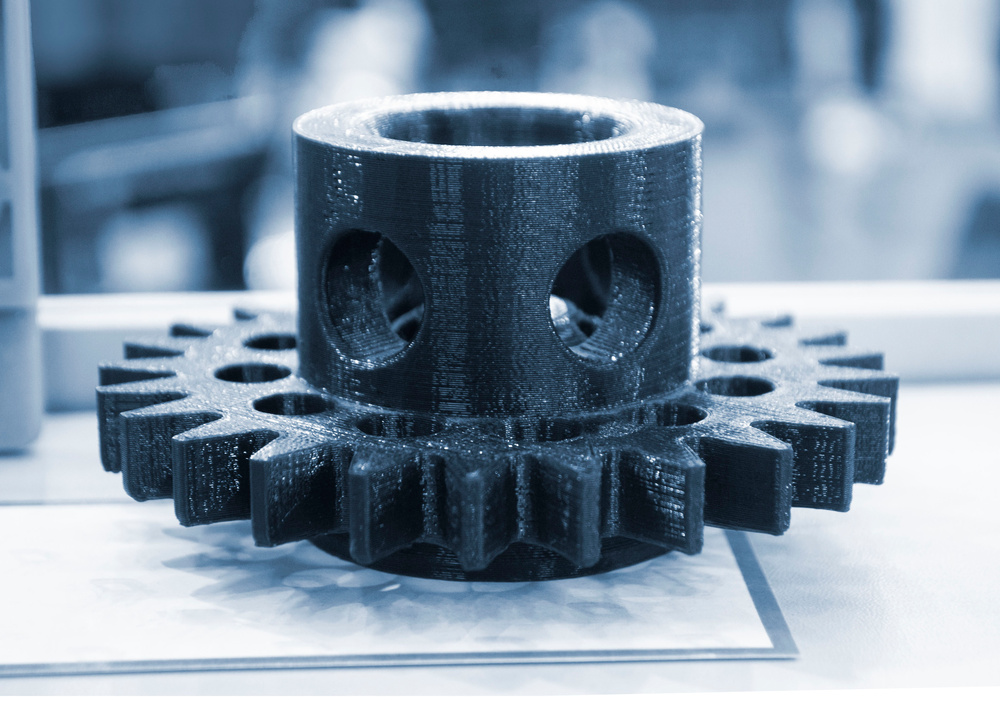

3D Printing Parts

Manufacture fully functional parts suitable for small-batch production or customized needs. These parts can be directly used for assembly or testing.

3D Printing Artworks

Create complex and exquisite artworks and decorations, achieving design effects that are difficult to reach with traditional craftsmanship.

3D Printing Toys

Produce personalized toys and models to meet consumers’ customized needs. These products are not only fun but also have high educational value.

**

Material Selection and Characteristics

Xiamen Goldcattle Factory can process multiple 3D printing materials, each with unique characteristics and application scenarios:

PLA Plastic

- Features: Environmentally friendly, non-toxic, easy to print, smooth surface

- Applications: Prototyping, artworks, educational models

- Advantages: Low printing temperature, not easily deformed, rich colors

ABS Plastic

- Features: High strength, good toughness, impact resistance

- Applications: Functional parts, automotive accessories, electronic housings

- Advantages: Excellent mechanical properties, can be post-processed

PETG Plastic

- Features: High transparency, chemical resistance, environmental protection

- Applications: Food containers, medical devices, cosmetic packaging

- Advantages: Safe and non-toxic, smooth surface, easy to bond

Nylon Material

- Features: High strength, good wear resistance, excellent flexibility

- Applications: Gears, bearings, functional parts

- Advantages: Excellent mechanical properties, wide application range

Technical Advantages and Features

Xiamen Goldcattle Factory’s 3D printing services have the following significant advantages:

High Precision Manufacturing

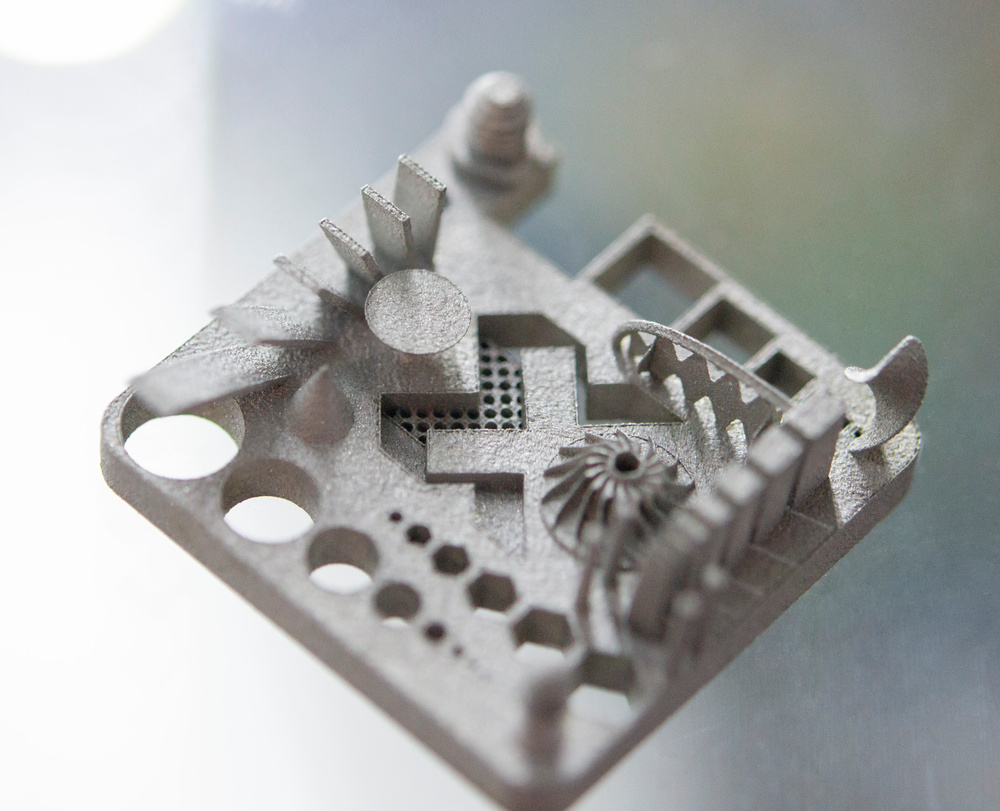

Printing accuracy can reach ±0.1mm, capable of producing products with rich details. This ensures the dimensional accuracy and appearance quality of the products.

Complex Structure Manufacturing

Able to manufacture complex internal structures that are difficult to achieve with traditional processes, such as hollow designs and cavity structures. This provides greater freedom for product design.

Material Diversification

Supports printing with multiple materials to meet the needs of different application scenarios. Customers can choose the most suitable material according to the functional requirements of the product.

Strong Customization

Able to quickly respond to customers’ customized needs and achieve small-batch, multi-variety production. This is particularly suitable for personalized products and innovative designs.

Service Process and Cases

Xiamen Goldcattle Factory provides professional 3D printing service processes for customers:

1. Needs Communication

Understand the specific needs of customers, including product usage, performance requirements, quantity, and delivery time.

2. Solution Design

According to customer needs, formulate detailed 3D printing plans, including material selection, process parameters, and cost budget.

3. Model Confirmation

Produce samples for customer confirmation and make necessary adjustments and optimizations based on feedback.

4. Mass Production

After confirming the samples, conduct mass production to ensure product quality and delivery time.

5. After-sales Service

Provide comprehensive after-sales service to solve problems encountered by customers during use.

Why Choose Xiamen Goldcattle

Strong Technical Capabilities

Possess advanced 3D printing equipment and professional technical teams, capable of handling various complex printing needs.

Rich Experience

26 years of manufacturing experience have accumulated rich technical and management experience, ensuring stable and reliable product quality.

Comprehensive Services

Provide one-stop services from design consultation to post-processing, offering comprehensive support to customers.

Accurate Delivery

Efficient production management and complete supply chain system ensure on-time delivery of customer orders.

Cost-effective

Reasonable prices and high-quality services create greater value for customers.

In this era of pursuing innovation and personalization, 3D printing technology has brought new development opportunities to the manufacturing industry. With its professional technical capabilities and rich manufacturing experience, Xiamen Goldcattle Factory has established a good reputation in the 3D printing field.

Whether for new product development, small-batch production, or personalized customization, Xiamen Goldcattle can provide satisfactory solutions. If you are looking for a reliable 3D printing service partner, consider Xiamen Goldcattle Factory. 26 years of dedication, all for the perfect presentation of every product.