With the rapid development of modern manufacturing industry, CNC machining technology has become an indispensable part of industrial production. Among them, 5-axis CNC machining technology has been widely used in many fields with its advantages of high precision, high efficiency and high flexibility.Xiamen Goldcattle, as a professional CNC machining service provider, is committed to providing high-quality 5-axis machining customized service to meet the diversified machining needs of customers.

①5-axis CNC machining technology

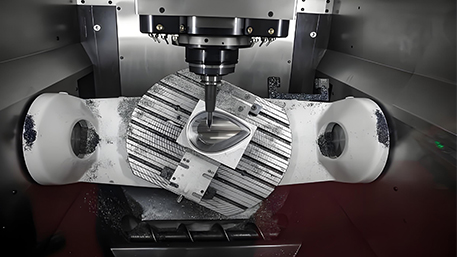

5-axis CNC machining technology is an advanced machining method, which realizes accurate machining of workpieces on complex spatial surfaces by integrating five axes of motion (usually including three linear axes X, Y, Z and two rotary axes A, B, or C) on the machine tool. This technology not only dramatically improves machining accuracy and efficiency, but also significantly reduces the degree of manual intervention, making mass production and customized machining of complex parts possible.

Technical Features

High precision: 5-axis CNC machine tool adopts advanced servo drive system and closed-loop control algorithm, which is able to realize micron-level machining precision and meet the machining requirements of high-precision parts.

High efficiency: By optimizing the tool path and reducing the number of tool changes, 5-axis machining can significantly shorten the machining cycle and improve productivity.

High Flexibility: The rotary axis design of the 5-axis machine allows the tool to approach the workpiece at any angle, realizing one-time machining of complex surfaces without the need for multiple clamping and turning.

Technical Advantages

According to industrial technology references, the use of 5-axis CNC machining technology can increase machining efficiency by 30%-50% and machining accuracy to within 0.01mm when machining complex parts compared to traditional 3-axis machining. In addition, 5-axis machining can effectively reduce material waste and machining costs, and improve the overall machining efficiency.

②Xiamen Goldcattle 5-axis machining customization service

With advanced 5-axis CNC machine tools, professional technical team and rich machining experience, Xiamen Goldcattle provides customers with a full range of 5-axis machining customized services.

Equipment Advantage

The company has introduced many high-performance 5-axis CNC machines, including DMG Mori from Germany, Mazak from Japan and other international famous brands. These machines have high precision, high rigidity, high stability and good dynamic performance, which can meet the processing needs of various complex parts.

Technical Strength

Xiamen Goldcattle has a team of senior engineers and technicians with rich experience and deep expertise in CNC machining. By using advanced CAD/CAM software for 3D modeling and tool path planning, the company is able to provide customers with accurate and efficient machining solutions.

Machining Scope

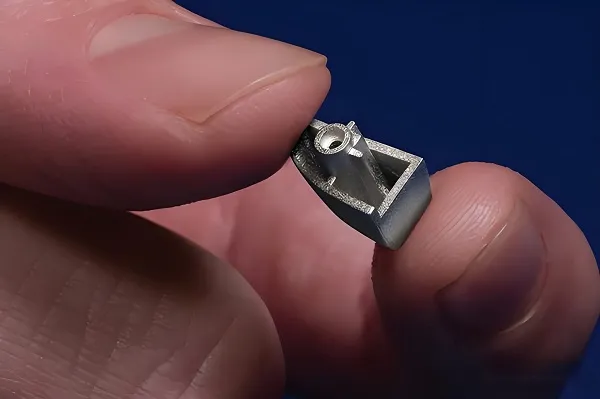

The company’s customized 5-axis machining services cover a wide range of fields, including aerospace, medical equipment, automotive manufacturing, and precision molds. Whether it is complex curved parts, precision hole machining or high-precision contouring, Xiamen Goldcattle can provide professional solutions.

Quality Assurance

The company has established a perfect quality management system, from raw material purchasing, production and processing to finished product inspection, every step of the process strictly follows the industry standards and customer requirements. By adopting advanced testing equipment and professional testing methods, we ensure that every product meets the quality standards.

Conclusion

Xiamen Goldcattle, as a professional 5-axis CNC machining service provider, is committed to providing customers with high-quality 5-axis machining customized services by virtue of advanced equipment, professional technical team and rich machining experience. In the future, the company will continue to uphold the “quality first, customer first” business philosophy, and constantly improve the level of technology and quality of service, for the development of the manufacturing industry to contribute more power.