Table of Contents

- The Importance of Injection Molding

- Xiamen Goldcattle’s Injection Molding Capabilities

- Injection Molding Process Flow

- Diversified Injection Molding Technologies

- Material Selection and Applications

- Why Choose Xiamen Goldcattle

The Importance of Injection Molding

In our daily lives, from mobile phone cases to automotive parts, from household appliances to medical devices, plastic products are everywhere. And the birth of these products cannot be separated from injection molding technology.

Injection molding is like the “magic factory” of modern manufacturing, capable of turning small plastic pellets into products of various complex shapes with high precision requirements. And Xiamen Goldcattle Factory is a leader in this field.

Xiamen Goldcattle’s Injection Molding Capabilities

As a national high-tech enterprise, Xiamen Goldcattle Factory has 26 years of manufacturing experience. In the field of injection molding, the factory is equipped with advanced injection molding equipment and a professional technical team.

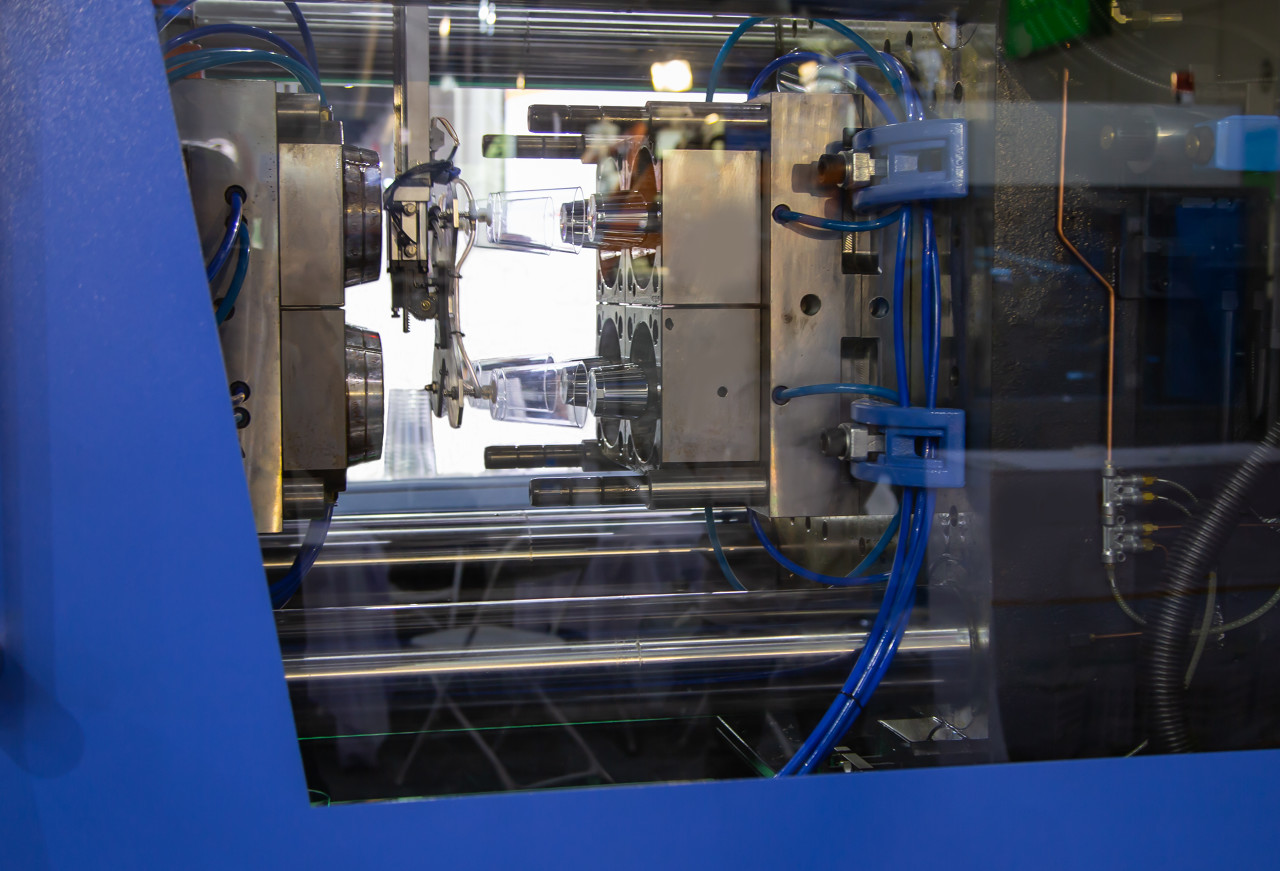

Walking into Xiamen Goldcattle injection molding workshop, you will see precision injection molding machines working in an orderly manner. These devices can produce various plastic products from micro parts to large components, meeting the needs of different customers.

Injection Molding Process Flow

Injection molding may seem simple, but it is actually a sophisticated systems engineering. Let’s see how a plastic part is born:

1. Material Preparation

First, select the appropriate plastic material according to product requirements. Xiamen Goldcattle can process various engineering plastics, including ABS, PP, PC, PA, etc.

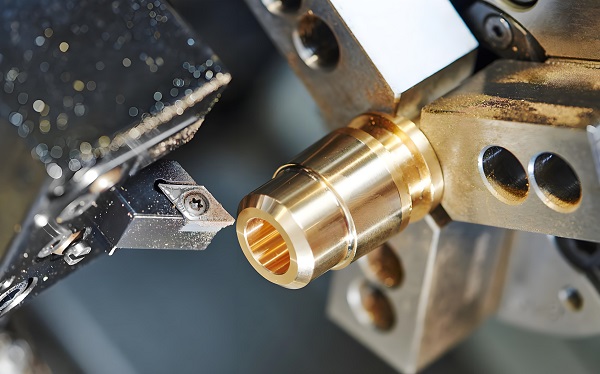

2. Mold Design and Manufacturing

The mold is the core of injection molding. Engineers design and manufacture high-precision molds according to product drawings to ensure product dimensional accuracy and surface quality.

3. Injection Molding

Plastic pellets are heated and melted, then injected into the mold cavity under high pressure. This step requires precise control of temperature, pressure, time and other parameters.

4. Cooling and Setting

The plastic injected into the mold is quickly set under the action of the cooling system, forming the shape of the final product.

5. Demolding and Part Removal

The mold opens, and the robotic arm removes the molded product for the next process.

6. Post-processing

Trimming, polishing, assembly and other subsequent processing are performed as needed to ensure product quality.

Diversified Injection Molding Technologies

Xiamen Goldcattle Factory has mastered a variety of advanced injection molding technologies to meet the needs of different products:

Single-color Injection Molding

The most basic injection molding technology, suitable for products with a single color.

Multi-color Injection Molding

Able to achieve multiple colors or multiple materials combination on the same product, such as products with soft and hard rubber combination.

Insert Injection Molding

Metal or other material inserts are placed into the mold, then plastic is injected to wrap them, forming composite products.

Foam Injection Molding

Special process creates tiny bubbles inside the plastic, reducing product weight and improving insulation performance.

Micro Injection Molding

Specialized for manufacturing precision parts with tiny dimensions, such as electronic connectors, medical parts, etc.

Material Selection and Applications

Xiamen Goldcattle Factory can process a variety of plastic materials, each with unique characteristics and application fields:

ABS Plastic

- Features: High strength, good toughness, easy processing

- Applications: Home appliance housings, automotive parts, toys

Polypropylene (PP)

- Features: Chemical resistance, good heat resistance, moderate price

- Applications: Food containers, medical devices, automotive accessories

Polycarbonate (PC)

- Features: High transparency, impact resistance, high temperature resistance

- Applications: Eyeglass lenses, optical discs, electronic and electrical parts

Nylon (PA)

- Features: High strength, good wear resistance, self-lubricating

- Applications: Gears, bearings, automotive parts

Quality Control System

Quality is Xiamen Goldcattle’s lifeline. The factory has established a complete quality management system to ensure every product meets customer requirements:

Raw Material Inspection

Strictly control raw material quality to ensure the plastic pellets used meet standards.

Process Control

Real-time monitoring of temperature, pressure, time and other key parameters during injection molding.

Finished Product Inspection

Each batch of products undergoes dimensional measurement, appearance inspection, performance testing and other inspection procedures.

Equipment Maintenance

Regular maintenance of injection molding equipment to ensure equipment precision and stability.

Xiamen Goldcattle has also obtained multiple international certifications including ISO9001, SGS, RoHS, CE, providing strong guarantee for product quality.

Customer Service Cases

Xiamen Goldcattle Factory’s injection molded products are widely used in multiple industries:

Automotive Industry

Provide various precision plastic parts for automotive manufacturers, such as interior parts, electronic component housings, etc.

Electronics Industry

Produce housings and internal parts for mobile phones, tablets, laptops and other electronic products.

Medical Devices

Manufacture plastic accessories for various medical equipment, requiring high cleanliness and biocompatibility.

Home Appliances

Provide plastic parts for washing machines, air conditioners, refrigerators and other home appliances.

Toy Industry

Produce various plastic toys, ensuring safety and non-toxicity.

Why Choose Xiamen Goldcattle

Strong Technical Capabilities

26 years of manufacturing experience, professional technical team, advanced equipment.

Good Product Quality

Strict quality control system, multiple international certifications, stable and reliable product quality.

Wide Service Range

Able to provide one-stop service from mold design to product delivery.

Guaranteed Delivery

Efficient production management ensures on-time delivery of customer orders.

Cost-effective

Reasonable prices and high-quality services create value for customers.

In the highly competitive injection molding industry, Xiamen Goldcattle Factory has won the trust and praise of customers with its professional technology, reliable quality and excellent service. Whether for mass production or small-batch customization, Xiamen Goldcattle can provide satisfactory solutions.

If you are looking for a reliable injection molding partner, consider Xiamen Goldcattle Factory. 26 years of dedication, only for every perfect plastic part.