In today’s deepening globalization, the cooperation between Xiamen Goldcattle and a famous American machinery manufacturer for CNC customization service is not only a collision of technology, but also a challenge to the limit of precision manufacturing. This cooperation journey is full of difficulties and challenges, but both parties wrote a success story together with professionalism and unremitting efforts.

1. Background of cooperation: the call of high-end demand

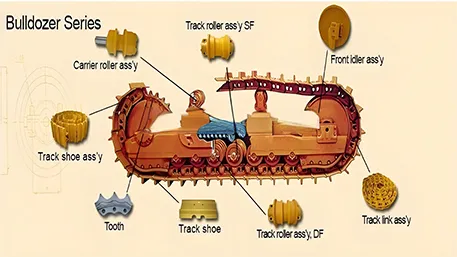

As a leader in the industry, U.S. manufacturers occupy an important position in many fields such as aerospace and automobile manufacturing. With the increasing demand for personalized, high-precision parts, they urgently need to find a partner that can provide high-quality CNC customization services. xiamen Goldcattle, with its advanced machining technology, strict quality control system and relentless pursuit of innovation, became their ideal choice.

2.Cooperation Difficulties and Challenges

Technical Difficulties: Micron-level Precision Requirements

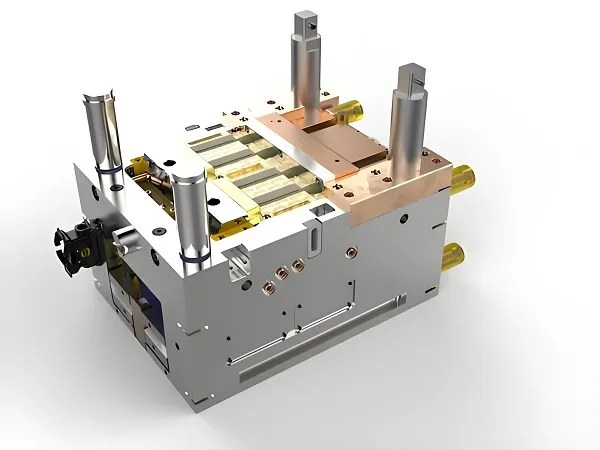

The core of the customization requirements put forward by U.S. manufacturers is the requirement for micron-level precision of parts. This means that during the machining process, any small deviation may lead to the failure of the whole product. xiamen Goldcattle’s technical team faced an unprecedented challenge. Not only do they need to make precise adjustments to the CNC machine tools, but they also need to continuously optimize the machining process to ensure that every cut is made with the ultimate precision.

Technical Seminars: Both teams organized several technical seminars and exchanged technical details, design requirements and machining difficulties through videoconferences and on-site visits; Xiamen Goldcattle’s technical experts explained in detail the performance of its CNC machines, machining ranges, and the level of precision it could achieve, while the American manufacturer shared its specific performance requirements for the parts and the application scenarios.

Customized solutions: Based on the in-depth communication, Xiamen Goldcattle’s technical team customized a set of machining solutions for the American manufacturer. This solution not only considered the precision requirements, but also took into account the production efficiency, material utilization and cost control and other aspects.

Material Selection: Balancing Performance and Cost

In order to meet the extreme conditions of high temperature, high pressure and corrosion resistance in the aerospace industry, the selection of materials for components is crucial, and Xiamen Goldcattle has explored a variety of new alloys with the US manufacturer and conducted extensive tests in the laboratory. They need to ensure the performance of the material while trying to control the cost in order to realize the competitiveness of the product in the market. This process involved countless communications and discussions between the two teams, and finally the optimal solution was found.

Commissioning of high-precision machine tools: Xiamen Goldcattle’s technicians carried out precise commissioning of the CNC machine tools to ensure that the machines would maintain stability and high precision during the machining process. By adjusting the control system of the machine, optimizing the tool path and cutting parameters, they successfully improved the machining accuracy to micron level.

Application of new materials: In response to the strict requirements of American manufacturers on material performance, Xiamen Goldcattle actively searched for and tested a variety of new alloy materials. Through many experiments and comparative analysis, they finally selected a material with superior performance and controllable cost, which meets the extreme conditions of aerospace components.

Simulation and real-time monitoring: In order to further improve production efficiency and product quality, Xiamen Goldcattle introduced advanced simulation software to virtually simulate the machining process. Through simulation, they can identify and solve potential problems in advance. At the same time, they also use automated production lines and intelligent monitoring systems to monitor and adjust the process in real time to ensure that every step of the process meets the design requirements.

Process Optimization: Improving Efficiency and Quality

In order to improve production efficiency and ensure product quality, Xiamen Goldcattle has fully optimized the CNC machining process. They introduced advanced simulation software to virtually model the machining process to anticipate and solve potential problems. At the same time, they also adopted automated production lines and intelligent monitoring systems to realize real-time monitoring and adjustment of the machining process. These measures not only improve productivity, but also significantly reduce the scrap rate.

3. Cross-border collaboration: the test of time and space

As a multinational cooperation project, both teams need to overcome obstacles such as time difference, language and cultural differences. In order to maintain close communication and collaboration, they set up a regular video conference system and a dedicated project management team to coordinate the work. In addition, Xiamen Goldcattle provided detailed processing progress reports and quality inspection data so that the US manufacturer could keep track of the project’s progress.

Achievements: Perfect Delivery Beyond Expectations

Through the joint efforts of both teams, the customized parts were delivered with a quality that exceeded the customer’s expectations. They not only met the micron-level precision requirements, but also showed excellent performance. The U.S. manufacturer spoke highly of these parts and indicated that they would continue to maintain long-term cooperation with Xiamen Goldcattle.

4.Creating the future together, going forward hand in hand

This cooperation not only witnesses Xiamen Goldcattle’s excellent strength and innovation in the field of CNC customization service, but also highlights the great potential of cooperation between China and the United States in the field of high-end manufacturing. In the future, with the deepening and expanding of the cooperation between the two sides, we have reason to believe that more wonderful stories will bloom on the world stage. xiamen Goldcattle and the U.S. manufacturers of the cooperation journey will continue to move forward in the exploration and innovation on the road for the development of the global manufacturing industry to contribute more power.