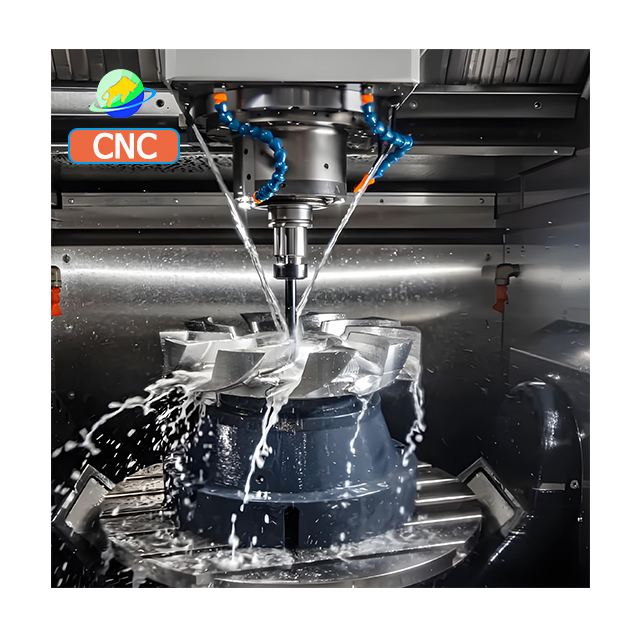

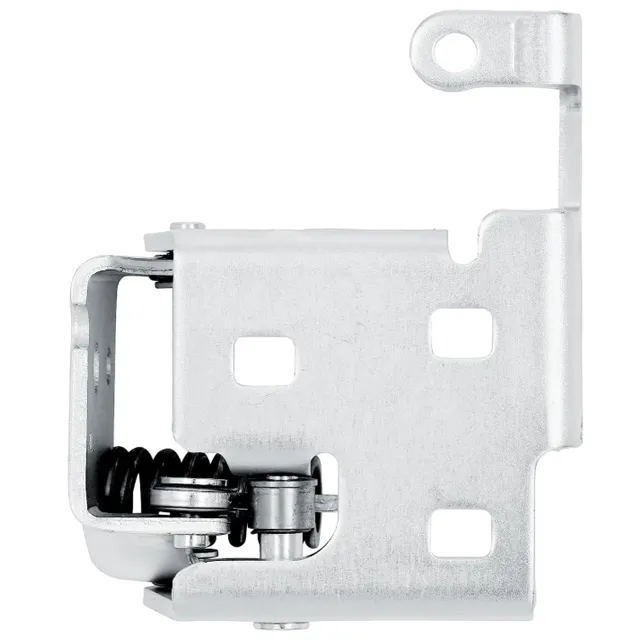

Custom Aerospace High Performance Light Alloy/Aluminum/Stainless Steel Saw Chain CNC Parts

Place of Origin:Fujian, China

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not:Micro Machining

Model Number:CMP-66

Brand Name:JSD

Product name:coustom chain saw parts

Service:Customized OEM

Material:Stainless Steel

Process:Cnc Machining+deburrs

Application:Industrial Equipment

Surface treatment:Plating

Keyword:CNC Macining Parts

Equipment:CNC Machining Centres

Name:Customized Machined CNC Machining

Item:CNC Precision Machining Part