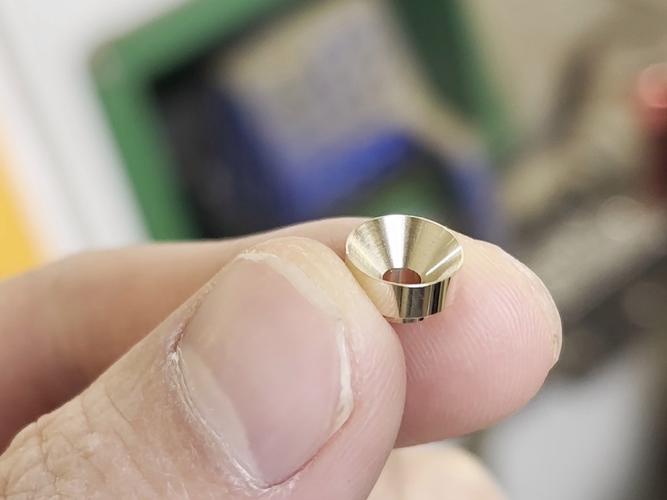

What Are CNC Brass Hardware Fittings? T

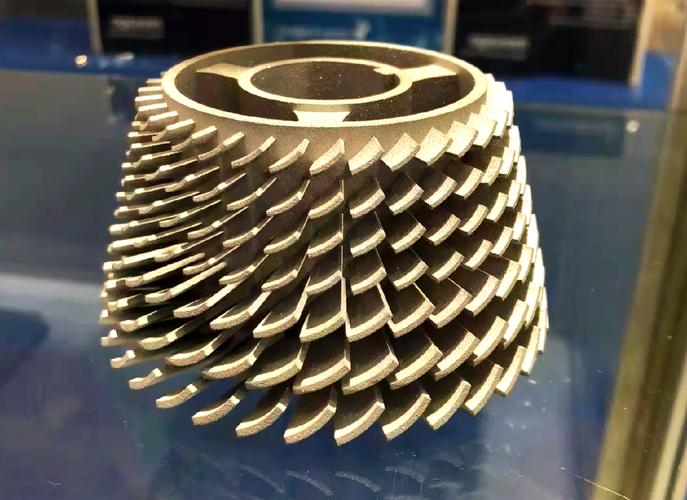

CNC brass hardware fittings refer to precision-manufactured components made from brass alloys using Computer Numerical Control (CNC) machining technology. Unlike manually crafted hardware, CNC brass fittings are produced via automated tools (e.g.,…