The answer is: The 4t rule is an important safety guideline for sheet metal bending! It tells us that the minimum inside bend radius should be four times the material thickness.

As an engineer with many years of experience in the sheet metal industry, I deeply understand the importance of the 4t rule in actual production. In sheet metal workshops, we transform flat metal sheets into various industrial parts through bending processes every day. This seemingly simple process actually contains profound mechanical principles.

You may have noticed that when metal sheets are bent at too sharp an angle, they easily crack at the bend, just like folding a piece of cardboard. This is not a material quality issue, but rather a result of the material’s inherent physical properties.

Want to know why this happens? Want to understand how the 4t rule serves as a “safety guide” for sheet metal engineers, ensuring every bend forms perfectly without damaging the material? Let’s explore this fundamental and most important design guideline in the industry from a professional perspective.

What is Sheet Metal Processing?

Before we understand the 4t rule, let me first explain what sheet metal processing is.

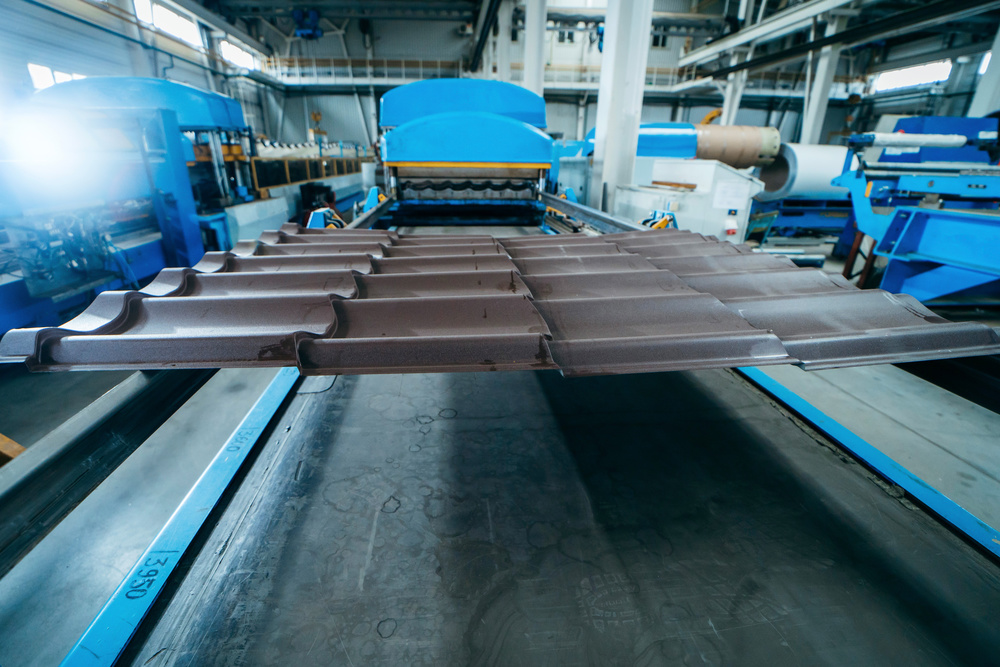

Sheet metal processing is the process of transforming flat metal sheets into various shapes. It’s like origami, but instead of folding paper, we fold hard metal sheets!

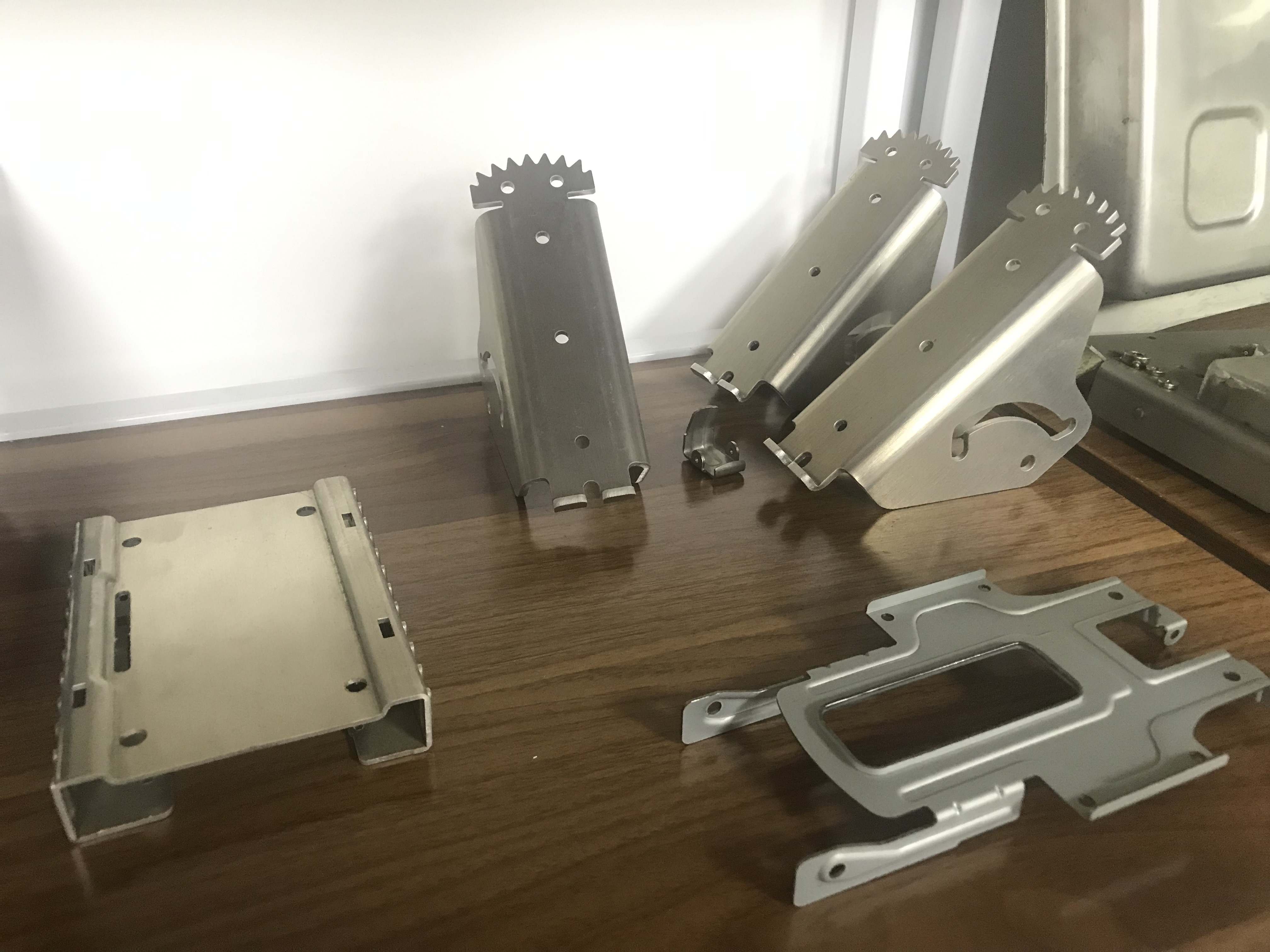

Look, these are parts made through sheet metal processing. They can be used to make computer cases, car parts, and even the casings of the appliances in our homes!

What Happens When Metal Sheets Are Bent?

When we bend a metal sheet, something amazing happens:

- Outer side stretches: The metal on the outer side of the bend stretches like a rubber band

- Inner side compresses: The metal on the inner side of the bend compresses like a spring

- Neutral layer in the middle: There’s a magical line in the middle of the metal sheet that neither stretches nor compresses, called the “neutral layer”

If the bend angle is too “sharp”, the outer metal stretches too much, exceeding its limit, and will crack like a potato chip!

What is the 4t Rule?

Now, let’s finally uncover the mystery of the 4t rule!

The 4t rule is an important safety guideline in sheet metal processing:

- 4: Represents a multiple, meaning four times

- t: Represents the thickness of the metal sheet (first letter of “thickness”)

- Rule: Represents the safety guideline we must follow

Simply put, the 4t rule states: The minimum inside bend radius should be four times the material thickness.

For example:

- If the metal sheet thickness is 1mm, the minimum bend radius should be 4mm

- If the metal sheet thickness is 2mm, the minimum bend radius should be 8mm

- If the metal sheet thickness is 3mm, the minimum bend radius should be 12mm

Why Do We Need the 4t Rule?

You might ask: Why must it be four times? Why not smaller?

This is because:

- Prevents cracking: If the bend radius is too small, the outer metal stretches too much and will crack

- Ensures part strength: Too small a bend radius weakens the part, making it prone to breaking

- Extends tool life: Proper bend radius protects expensive tools, making them last longer

- Reduces costs: Following the 4t rule reduces scrap, saving materials and time

The Scientific Principle Behind the 4t Rule

Let’s understand the scientific principle behind the 4t rule:

When a metal sheet bends, the tensile stress on the outer side and compressive stress on the inner side need to remain balanced. Through extensive experiments, scientists discovered that this balance is most stable when the bend radius is four times the material thickness, making the metal sheet least likely to fail.

It’s like folding a paper airplane:

- If the crease is too “sharp”, the paper will tear

- If the crease is more “gradual”, the paper won’t tear easily

The same principle applies to metal sheets!

Practical Application of the 4t Rule

How is the 4t rule applied in actual factory production?

Design Phase

Engineers determine bend radii based on the 4t rule when designing parts. They use specialized software on computers to simulate and ensure designs comply with the 4t rule.

Processing Phase

Operators select appropriate tools when operating bending machines. Tool dimensions directly affect bend radius and must meet the requirements of the 4t rule.

Inspection Phase

After processing, quality inspectors use specialized tools to measure bend radii, ensuring they meet the requirements of the 4t rule.

Related Implementation Standards

In the sheet metal industry, there are many related standards and specifications, with the 4t rule being the most fundamental and important one.

National Standards

- GB/T 1184: Geometric tolerancing standards

- GB/T 1804: General tolerancing standards

- QJ/ZDS 2201-A: Sheet metal development design process standards

These standards are like the “traffic rules” of the industry, ensuring all sheet metal parts meet safety and quality requirements.

Industry Specifications

Different industries have their own special requirements:

- Automotive industry: Requires higher precision and strength

- Electronics industry: Requires thinner materials and smaller dimensions

- Aerospace: Requires the highest safety and reliability

Exceptions to the 4t Rule

Although the 4t rule is an important safety guideline, there can be exceptions in certain special circumstances:

Material Properties

- Soft materials: Metals like aluminum and copper that are relatively soft can use bend radii smaller than 4t

- Hard materials: Harder metals like high-strength steel and titanium alloys may require bend radii larger than 4t

Processing Techniques

- Hot bending: Heated metal bends more easily and can use smaller bend radii

- Special tools: Using specially designed tools can also achieve smaller bend radii

Special Requirements

In some special products, to meet specific functional requirements, engineers use bend radii smaller than 4t after rigorous calculations and testing. However, this requires very specialized knowledge and extensive experience.

Safety Precautions

Safety is always the top priority in sheet metal processing!

- Wear protective equipment: Always wear safety glasses and gloves when operating bending machines

- Professional operation: Bending machines are very dangerous equipment and must be operated by professionals

- Regular inspections: Frequently check if equipment and tools are in normal condition

- Follow procedures: Strictly follow operating procedures and safety standards

Professional Summary

Through years of industry practice, I deeply recognize the important value of the 4t rule. This seemingly simple design guideline is actually the crystallization of countless engineers’ experiences.

What impresses me most is that the 4t rule wasn’t imagined out of thin air, but was derived through extensive experimental data and actual production verification. It embodies the integration of knowledge from multiple disciplines such as material mechanics and metal processing technology, representing wisdom in industrial production.

Conclusion

After in-depth professional analysis, I can confidently say: The 4t rule is an extremely important safety guideline in sheet metal processing!

It tells us that the minimum inside bend radius should be four times the material thickness. This simple rule prevents metal sheets from cracking, ensures part strength, extends tool life, and reduces production costs.

I believe that with technological development, sheet metal processing technology will become increasingly advanced, but the 4t rule, as a fundamental safety guideline, will always be followed and passed down in the industry!