Concrete plastic mold, as an innovative molding tool, plays an important role in the fields of construction, municipal engineering and landscaping. It utilizes the properties of polymer materials, combined with the structural needs of concrete, and is made through a specific manufacturing process. It is specially used to form and fix concrete or cement mixtures, ensuring that they form precise shapes and structures during hardening.

1.Technical principle of concrete plastic mold

The technical principle of plastic concrete molds lies in combining the advantages of concrete and plastic. Plastic material, because of its light weight, easy processing, good weather resistance and other characteristics, combined with the high strength and durability of concrete to form a new type of mold material. In the manufacturing process, through the steps of mold design, material proportioning, precise processing, etc., the mold maintains a stable shape during the concrete pouring process and is easily demolded after the concrete hardens, thus obtaining high-quality concrete products.

2.Customization of concrete plastic mold products

Concrete plastic molds support highly customized services to meet the specific needs of different projects. The customization process usually includes the following steps:

Demand analysis: Understand the customer’s specific needs, including mold shape, size, material requirements and so on.

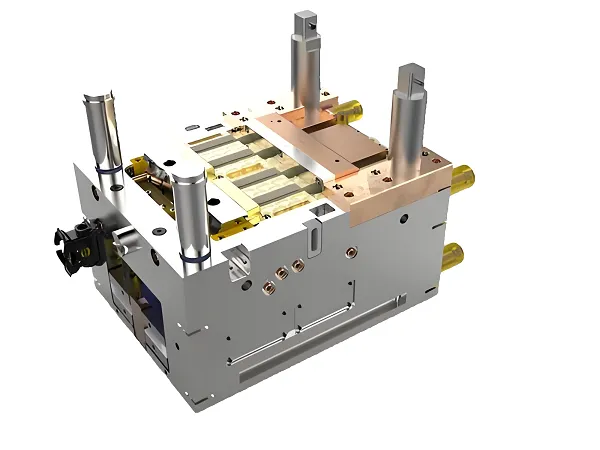

Mold design: Use CAD software to design the mold to ensure the accuracy and feasibility of the mold.

Material Selection: According to the use and requirements of the mold, select the appropriate plastic or composite material as the mold material.

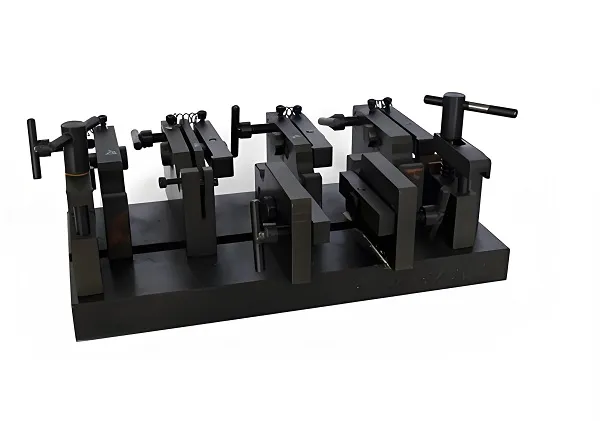

Precision Processing: CNC machine tools are used for precision processing to ensure the accuracy and surface finish of the mold.

Finished product testing: After the mold is finished, conduct finished product testing to verify whether its performance and quality meet the requirements.

3.Introduction of concrete plastic mold materials

Commonly used materials for concrete plastic molds include the following:

Plastic: such as polypropylene (PP), polycarbonate (PC), etc., with light weight, easy processing, low cost and so on. However, its strength is relatively low, suitable for making basic and simple components.

●Light weight, good weather resistance, and easy processing.

●Low cost and good molding effect.

High surface finish.

● Relatively short service life.

Glass Fiber Reinforced Plastic: High strength and hardness, suitable for making complex and demanding molds.

●High strength and hardness.

●Good wear resistance and long service life.

●Good surface finish.

Relatively high cost.

4.Concrete plastic mold product characteristics

Product: Concrete plastic mold

●High dimensional accuracy, can be controlled within ±1mm.

●Good surface finish, Ra value can reach below 0.8μm.

●Light weight, compared with the traditional steel mold, the weight can be reduced by more than 50%.

●Good weather resistance, can be used in the temperature range of -40℃ to +60℃.

●High turnover times, generally up to 200 times or more.

Concrete plastic mold FAQ

Q1: What are the advantages of concrete plastic molds over traditional steel molds?

A: Concrete plastic mold has the advantages of light weight, easy processing, low cost, good weather resistance, etc. It can reduce the labor intensity of workers, improve the production efficiency, and at the same time reduce energy consumption and environmental pollution.

Q2:How to choose the right material for concrete plastic mold?

A: Choosing the right concrete plastic mold material needs to be considered according to the demand of the specific project, the shape and size of the mold, the use of the environment and other factors. Generally speaking, for basic and simple components, plastic materials can be chosen; for complex and highly demanding molds, materials such as glass fiber reinforced plastic can be chosen.

Q3:What are the precautions for the maintenance of concrete plastic mold?

A: The maintenance of concrete plastic mold needs to pay attention to the following points: avoid long time exposure to sunlight or high temperature environment; clean the surface of the mold in time after use to avoid concrete residue; check the wear and tear of the mold on a regular basis, and replace the damaged parts in time; avoid heavy pressure and extrusion when storing, and keep the mold flat and intact.