How long does injection molding take?

1、Answer The total time for injection molding varies widely: Single part cycle time: 10 seconds to 5+ minutes, depending on material (e.g., fast-cooling thermoplastics vs. slow-curing thermosets) and part…

1、Answer The total time for injection molding varies widely: Single part cycle time: 10 seconds to 5+ minutes, depending on material (e.g., fast-cooling thermoplastics vs. slow-curing thermosets) and part…

1、Answer No, injection molding is not only for plastic. While plastics are the most common materials, the process also works for metals (via metal injection molding, MIM), ceramics (CIM), rubber, and even food materials (e.g., chocolate). Each material requires…

1、Answer There is no absolute superiority; it depends on requirements: 3D printing is better for: Low-volume production (<500 pieces), complex curved/hollow structures (e.g., aerospace engine blades), and customized personalization…

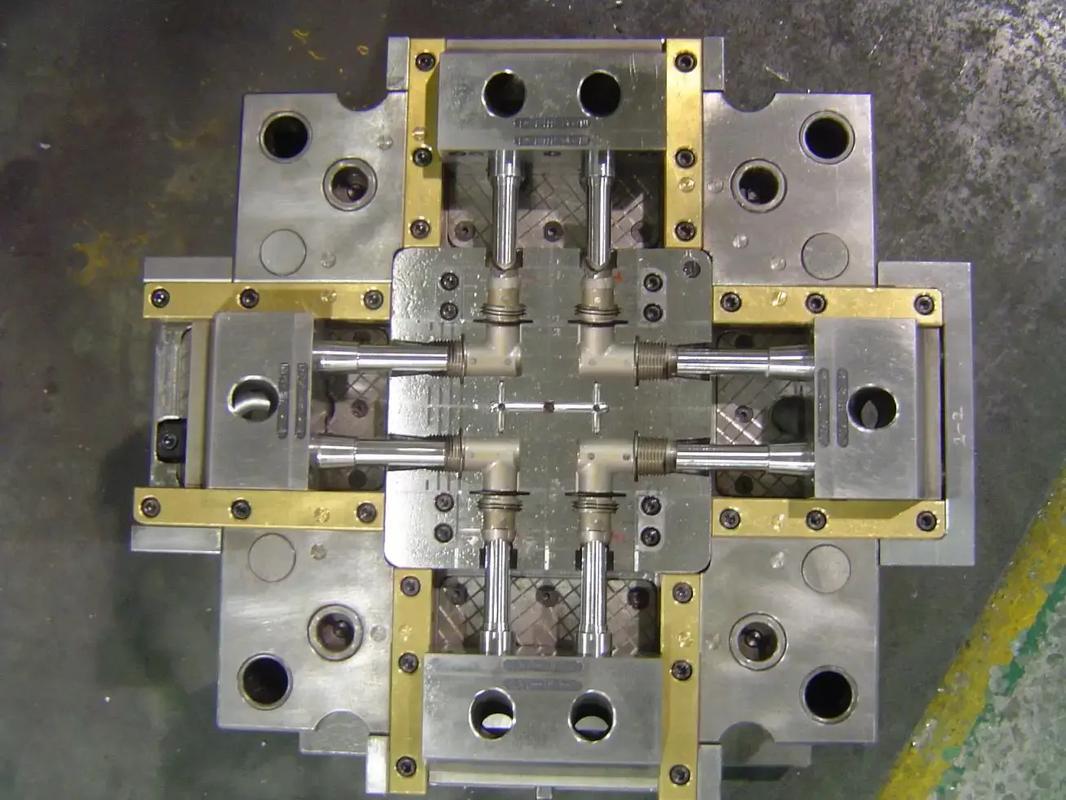

1、Answer The core reasons for the high cost of injection molding include: High mold costs: Molds need to be made of high – strength steel (such as H13 die steel)…

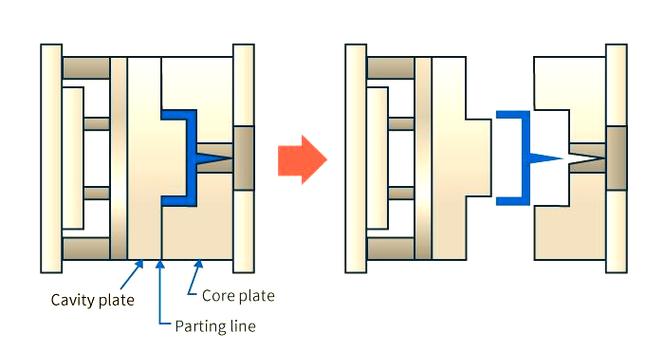

Answer: The injection molding process involves heating plastic raw materials to a molten state, applying pressure through the screw or plunger of an injection molding machine to inject the molten…

In the fields of large – scale equipment manufacturing such as automotive, aerospace, and home appliances, large – scale injection – molded parts, with their characteristics of integral molding and…

Against the backdrop of rapid product iteration and a surge in personalized demands, low – volume injection molding processing services have become crucial for enterprises to achieve agile development and…

On the fast – paced track of product research, development, and innovative iteration, prototyping injection molding services, through data – driven precise processes, rapid tooling technologies, and a full –…

In the field of industrial manufacturing, customized injection – molded parts, with their advantages of high efficiency, high precision, and low cost, have become key components in industries such as…

Against the backdrop of the modern manufacturing industry’s transformation towards high precision and miniaturization, custom precision injection – molded parts, with their characteristics of precise dimensions, functional integration, and efficient…