In the dynamic landscape of modern manufacturing, CNC machining stands as a cornerstone technology, revolutionizing the way parts and components are produced. This article aims to provide a comprehensive and in – depth understanding of the CNC machining definition, exploring its key elements, working principles, and significance in various industries.

What is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that relies on pre – programmed computer software to control the movement of machine tools. It represents a significant advancement from traditional manual machining methods, where operations were carried out by hand – controlled tools.

In CNC machining, a digital model of the desired part is created using computer – aided design (CAD) software. This model contains all the necessary geometric information about the part, such as its shape, dimensions, and tolerances. The CAD model is then translated into a set of instructions, known as a CNC program, using computer – aided manufacturing (CAM) software. This program precisely dictates the movement of the cutting tools, spindle speed, feed rate, and depth of cut during the machining process.

The Working Principles of CNC Machining

At its core, CNC machining operates through a closed – loop control system. The CNC machine consists of a machine tool (such as a mill, lathe, or router), a control unit, and a series of motors and drives that move the tool and the workpiece.

When the CNC program is loaded into the control unit, the control unit reads the instructions and sends electrical signals to the motors. These motors drive the linear and rotational axes of the machine tool, causing the cutting tool to move in the precise path defined by the program. Sensors on the machine monitor the position and performance of the tool and the workpiece, providing feedback to the control unit. This feedback loop allows the control unit to make real – time adjustments to ensure that the machining process stays within the specified tolerances.

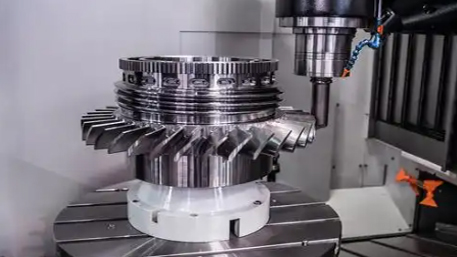

For example, in a CNC milling machine, the cutting tool rotates at a high speed while moving along multiple axes (X, Y, and Z) to remove material from the workpiece, gradually shaping it into the desired part. The movement of the tool is so precise that it can create complex geometries with extremely tight tolerances.

Key Components of CNC Machining

Machine Tools

As mentioned earlier, various types of machine tools are used in CNC machining. CNC mills are versatile machines capable of performing a wide range of operations, including cutting, drilling, and contouring. They are ideal for creating flat or three – dimensional parts. CNC lathes, on the other hand, are used for turning operations, where the workpiece rotates while the cutting tool removes material to create cylindrical or conical shapes. CNC routers are often employed for working with materials like wood, plastics, and composites, using a rotating cutting bit to carve out the desired shape.

CNC Control Unit

The CNC control unit is the brain of the CNC machining system. It interprets the CNC program, sends commands to the motors, and manages the overall machining process. Modern CNC control units are highly advanced, with user – friendly interfaces that allow operators to monitor and adjust the machining parameters during the process.

Cutting Tools

Cutting tools play a crucial role in CNC machining. Different types of cutting tools are used depending on the material being machined and the operation being performed. For example, carbide – tipped end mills are commonly used for machining metals, while high – speed steel drills are suitable for a variety of materials. The proper selection of cutting tools is essential for achieving high – quality results and efficient machining.

Significance of CNC Machining in Different Industries

Aerospace Industry

In the aerospace industry, where precision and quality are of utmost importance, CNC machining is extensively used. Aircraft components such as engine parts, wing structures, and landing gear components are often manufactured using CNC machining. The ability to achieve tight tolerances and produce complex geometries ensures the safety and performance of aircraft.

Automotive Industry

The automotive industry also benefits greatly from CNC machining. Parts like engine blocks, transmission components, and custom – made automotive parts can be produced with high precision and consistency using CNC machines. This helps in improving the overall quality and performance of vehicles, as well as enabling the production of new and innovative designs.

Medical Device Manufacturing

Medical device manufacturing requires parts that meet extremely high standards of precision and quality. CNC machining is used to produce components for surgical instruments, implants, and diagnostic equipment. The ability to create parts with intricate designs and tight tolerances is crucial for ensuring the effectiveness and safety of medical devices.

CNC machining is a sophisticated manufacturing process that combines computer technology, advanced control systems, and precision machine tools. Its definition encompasses the use of pre – programmed instructions to control the movement of machine tools, enabling the production of high – quality, complex parts with remarkable precision. As technology continues to evolve, CNC machining will likely play an even more significant role in driving innovation and efficiency across