- Part function (e.g., structural load-bearing vs. decorative);

- Production volume (low-batch prototypes vs. high-volume mass production);

- Performance requirements (strength, weight, corrosion resistance);

- Cost constraints (material + tooling + post-processing).

1. Mainstream Die Casting Metals: Properties & Applications

1.1 Zinc Alloys (Zamak Series: 3, 5, 7)

Key Characteristics

|

Property

|

Zamak 3 (Most Common)

|

Zamak 5 (High-Strength)

|

Zamak 7 (Low-Lead)

|

|

Composition

|

Zn (96.5%), Al (3.3%), Mg (0.05%), Cu (0.03%)

|

Zn (95.5%), Al (4.0%), Mg (0.05%), Cu (0.5%)

|

Zn (95.8%), Al (3.9%), Mg (0.05%), Cu (0.25%), Pb <0.004%

|

|

Melting Point

|

380–420°C

|

385–425°C

|

380–420°C

|

|

Tensile Strength

|

320 MPa (46,400 psi)

|

380 MPa (55,100 psi)

|

350 MPa (50,800 psi)

|

|

Density

|

6.6 g/cm³

|

6.7 g/cm³

|

6.6 g/cm³

|

|

Corrosion Resistance

|

Moderate (prone to white rust in saltwater)

|

Good (Cu addition boosts resistance)

|

Moderate (lead-free for RoHS compliance)

|

|

Fluidity

|

Excellent (fills 0.5mm thin walls)

|

Very Good

|

Excellent

|

|

Tooling Compatibility

|

P20/H13 steel (low wear)

|

P20/H13 steel

|

P20/H13 steel

|

Advantages

- Lowest melting point (380–425°C): Reduces die wear (extends die life by 20–30% vs. aluminum) and energy costs.

- Superior fluidity: Captures fine details (e.g., 0.1mm engravings) for decorative parts.

- Cost-efficient: Material cost ((2.5–)3.5/kg) + tooling cost (30% lower than aluminum for small parts) = low per-unit cost for high volume.

Limitations

- High density: Not suitable for weight-sensitive applications (e.g., aerospace components).

- Low temperature resistance: Softens above 100°C (avoid engine bay or high-heat parts).

Typical Applications

- Consumer goods: Toy vehicles (1:24 die cast models), zippers, door handles, electronics housings (e.g., remote controls).

- Automotive: Interior components (air vent grilles, gear knobs), sensor brackets.

- Medical: Low-contact devices (e.g., wheelchair armrests—lead-free Zamak 7 for biocompatibility).

1.2 Aluminum Alloys (A380, A360, A413)

Key Characteristics

|

Property

|

A380 (Most Versatile)

|

A360 (Corrosion-Resistant)

|

A413 (High-Fluidity)

|

|

Composition

|

Al (92%), Si (7.5%), Cu (3.5%), Mg (0.1%)

|

Al (95%), Si (5%), Mg (0.5%)

|

Al (94%), Si (6%), Zn (0.3%)

|

|

Melting Point

|

580–650°C

|

590–650°C

|

585–640°C

|

|

Tensile Strength

|

310 MPa (45,000 psi)

|

280 MPa (40,600 psi)

|

290 MPa (42,100 psi)

|

|

Density

|

2.7 g/cm³

|

2.7 g/cm³

|

2.7 g/cm³

|

|

Corrosion Resistance

|

Good (anodizable for outdoor use)

|

Excellent (Mg addition for marine environments)

|

Good

|

|

Fluidity

|

Very Good (fills 0.8mm walls)

|

Good

|

Excellent (for thin parts)

|

|

Tooling Compatibility

|

H13 steel (high wear resistance)

|

H13 steel

|

H13 steel

|

Advantages

- Lightweight: 60% less dense than zinc—critical for weight-sensitive parts (e.g., electric vehicle components).

- High strength-to-weight ratio: Outperforms zinc in load-bearing scenarios (e.g., automotive structural brackets).

- Temperature resistance: Maintains strength up to 150°C (suitable for engine bay parts).

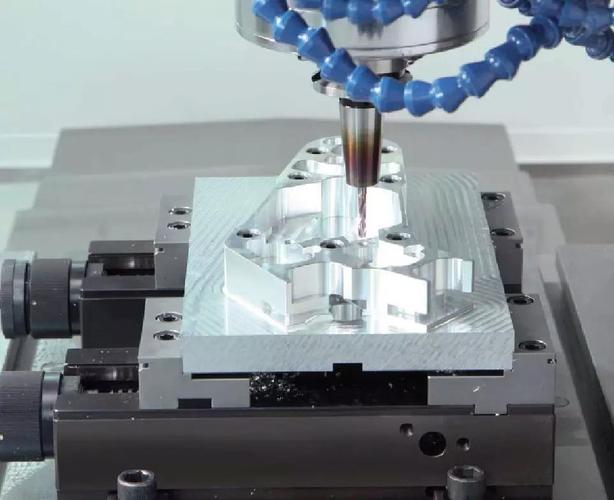

Limitations

- Higher melting point: Increases die wear (H13 steel required, vs. P20 for zinc) and energy costs.

- Lower fluidity: Struggles with <0.8mm thin walls (needs precision tooling to avoid incomplete filling).

Typical Applications

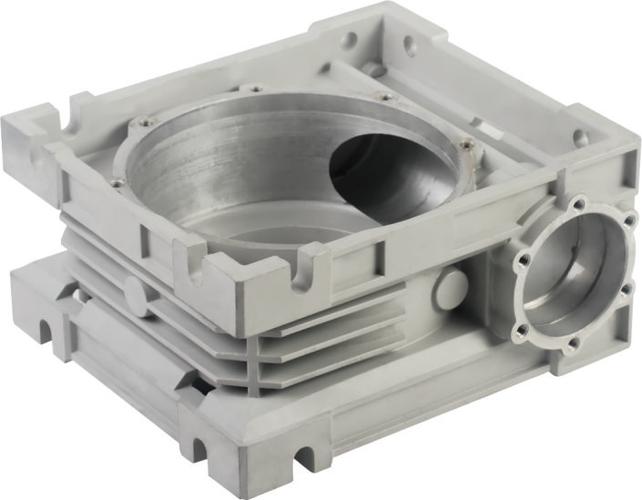

- Automotive: Transmission housings, engine brackets, EV battery casings (A380), wheel hubs (A360).

- Industrial: Pump bodies, valve components, heat sinks (aluminum’s thermal conductivity = 150 W/m·K, 3x zinc’s).

- Outdoor: Lighting fixtures (A360 with powder coating for corrosion resistance), solar panel frames.

1.3 Magnesium Alloys (AZ91D, AM60B)

Key Characteristics

|

Property

|

AZ91D (Most Common)

|

AM60B (High-Impact)

|

|

Composition

|

Mg (90%), Al (9%), Zn (1%), Mn (0.1%)

|

Mg (94%), Al (6%), Mn (0.1%)

|

|

Melting Point

|

590–650°C

|

600–650°C

|

|

Tensile Strength

|

230 MPa (33,400 psi)

|

270 MPa (39,200 psi)

|

|

Density

|

1.8 g/cm³

|

1.8 g/cm³

|

|

Corrosion Resistance

|

Poor (requires coating: e.g., chromate conversion)

|

Moderate (higher Al boosts resistance)

|

|

Fluidity

|

Good (fills 1.0mm walls)

|

Very Good

|

|

Tooling Compatibility

|

H13 steel (with anti-stick coating)

|

H13 steel

|

Advantages

- Ultra-lightweight: Enables fuel savings (automotive) or payload increases (aerospace).

- High impact resistance: AM60B outperforms aluminum in crash scenarios (used for EV door beams).

Limitations

- High cost: Material ((8–)12/kg) + specialized tooling (anti-flammability systems) = 2–3x more expensive than aluminum.

- Flammability risk: Molten magnesium ignites in air—requires inert gas (CO₂) during casting.

Typical Applications

- Aerospace: Drone frames, satellite components (weight reduction = launch cost savings).

- Automotive: EV seat frames, steering columns (AZ91D), crash structures (AM60B).

- Electronics: Laptop chassis (lightweight + rigid for portability).

1.4 Copper Alloys (Brass C36000, Bronze C95400)

Key Characteristics

|

Property

|

Brass C36000 (Free-Cutting)

|

Bronze C95400 (Aluminum Bronze)

|

|

Composition

|

Cu (60%), Zn (40%)

|

Cu (85%), Al (10%), Fe (5%)

|

|

Melting Point

|

900–940°C

|

1020–1080°C

|

|

Tensile Strength

|

415 MPa (60,200 psi)

|

690 MPa (100,100 psi)

|

|

Density

|

8.5 g/cm³

|

7.8 g/cm³

|

|

Electrical Conductivity

|

45% IACS (International Annealed Copper Standard)

|

15% IACS

|

|

Tooling Compatibility

|

H13 steel (high wear—requires cooling)

|

H13 steel (with heat-resistant coating)

|

Advantages

- High conductivity: Brass C36000 is used for electrical connectors (e.g., terminal blocks).

- Extreme wear resistance: Bronze C95400 for high-friction parts (e.g., pump impellers, valve seats).

Limitations

- Highest melting point: Causes severe die wear (die life <50k cycles, vs. 500k for zinc).

- High cost: Material ((9–)15/kg) + tooling = only viable for high-value parts.

Typical Applications

- Electrical: Terminal blocks, circuit board connectors (brass C36000).

- Industrial: Hydraulic valve cores, marine propeller components (bronze C95400, corrosion-resistant in saltwater).

2. Decision Framework: How to Choose the Right Metal

Step 1: Define Part Function & Performance Needs

|

Part Type

|

Key Requirement

|

Recommended Metals

|

|

Decorative (e.g., toys, jewelry)

|

Fine detail, low cost

|

Zamak 3/7

|

|

Structural (e.g., brackets, housings)

|

Strength, lightweight

|

Aluminum A380, Magnesium AZ91D

|

|

Weight-critical (e.g., drones, EVs)

|

Low density, high strength

|

Magnesium AZ91D/AM60B

|

|

High-wear (e.g., valves, impellers)

|

Wear resistance

|

Bronze C95400, Brass C36000

|

|

Outdoor/marine

|

Corrosion resistance

|

Aluminum A360, Bronze C95400

|

Step 2: Match to Production Volume

- Low volume (<10k units): Prioritize low tooling cost—Zamak 3 (P20 steel dies) or aluminum A380 (small single-cavity dies).

- High volume (>100k units): Prioritize per-unit cost—Zamak 5 (low material cost) or aluminum A380 (high production speed).

Step 3: Balance Cost & Performance

|

Budget Tier

|

Metal Option

|

Cost Breakdown (100k units)

|

|

Economy ($<5/part)

|

Zamak 3

|

Material: (2.5k + Tooling: )10k = $12.5k total

|

|

Mid-Range ((5–)15/part)

|

Aluminum A380

|

Material: (8k + Tooling: )15k = $23k total

|

|

Premium ($>15/part)

|

Magnesium AZ91D/Bronze C95400

|

Material: (20k + Tooling: )25k = $45k total

|

3. Common Myths & Misconceptions

Myth 1: “The strongest metal is the best choice.”

Myth 2: “Zinc is only for cheap, low-quality parts.”

Myth 3: “Magnesium is too flammable to use safely.”

Myth 4: “Copper alloys are obsolete for die casting.”

4. Industry Case Studies: Metal Selection in Practice

Case 1: Automotive EV Battery Casing

- Requirement: Lightweight (reduce vehicle weight), structural strength (protect cells), corrosion resistance (underbody exposure).

- Initial Choice: Zinc Zamak 5 (low cost) → Failed: Too heavy (added 15kg to vehicle weight) and poor corrosion resistance.

- Final Choice: Aluminum A380 (anodized) → Success: 60% lighter than zinc, 310 MPa tensile strength, and 5-year corrosion resistance in road salt.

Case 2: Drone Frame Production

- Requirement: Ultra-lightweight (max 200g), high impact resistance (crash survival), high volume (100k units/year).

- Initial Choice: Aluminum A380 → Failed: Too heavy (frame weight 250g, exceeding limit).

- Final Choice: Magnesium AZ91D → Success: Frame weight 180g, 230 MPa tensile strength, and 30% lower per-unit cost than carbon fiber (the alternative).

Case 3: Marine Valve Component

- Requirement: Corrosion resistance (saltwater), wear resistance (valve seating), high pressure (10 MPa).

- Initial Choice: Aluminum A360 → Failed: Wear rate too high (valve leakage after 6 months).

- Final Choice: Bronze C95400 → Success: No leakage after 2 years, 690 MPa tensile strength, and compatibility with seawater chemistry.

5. Conclusion: No “Best”—Only “Most Suitable”

- Choose zinc alloys for low-cost, detailed, high-volume parts (toys, electronics).

- Choose aluminum alloys for lightweight, structural, industrial/automotive parts (brackets, housings).

- Choose magnesium alloys for weight-critical, high-performance parts (drones, EVs).

- Choose copper alloys for conductive, high-wear parts (electrical connectors, valves).