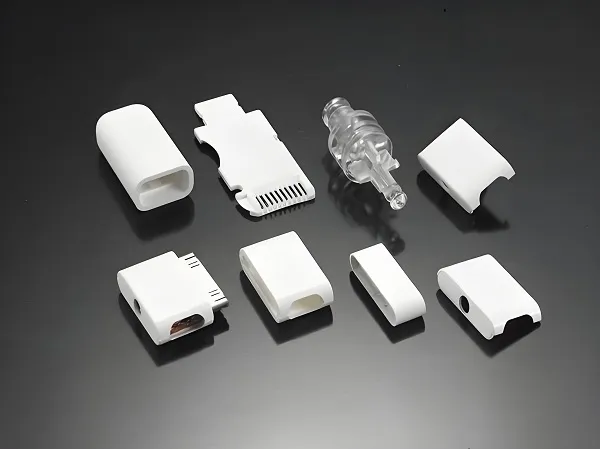

ABS injection molded parts are a common type of plastic parts processing in the machinery industry, whose full name is acrylonitrile-butadiene-styrene copolymer injection molded parts. These parts are manufactured through the injection molding process and have excellent overall properties, such as good impact strength, heat resistance, low temperature resistance, chemical resistance, and electrical properties, as well as being easy to process and surface treat. The following is a detailed analysis of ABS injection molded parts:

1.ABS injection molding material properties

Excellent comprehensive performance: ABS material combines the chemical resistance of acrylonitrile, the elasticity of butadiene and the rigidity of styrene, which makes ABS injection molded parts outstanding in a number of aspects.

Good processing performance: ABS material has good fluidity, easy to injection molding, can produce complex shapes, high precision parts.

Various surface treatments: The surface of ABS parts can be treated with various treatments, such as spraying, plating, etc., to meet different appearance and performance requirements.

2.Customized ABS injection molding parts process

The process of customizing ABS injection molded parts involves a number of key steps and considerations to ensure that the final product meets design requirements and has good performance. Below is a detailed customization process and related points:

● Requirements analysis and design

Requirements communication: First, the customer and the manufacturer need to communicate fully to clarify the specific needs of the part, including size, shape, quantity, material requirements (e.g., specific grades of ABS, color, transparency, etc.), the environment in which it is to be used, and any special performance requirements (e.g., strength, abrasion resistance, weather resistance, etc.).

Design: According to the customer’s needs, the designer draws a detailed 3D model or 2D drawing using CAD (Computer Aided Design) software. Factors such as material fluidity, cooling effect, mold structure, etc. need to be considered during the design process to ensure smooth injection molding and final product quality.

Material Selection and Purchasing

Material selection: According to the design requirements and product usage, select the appropriate ABS material, which has excellent processability, mechanical properties and chemical resistance, and is widely used in automotive, electronics, home appliances and other fields.

Material Purchase: Purchase the selected ABS material from reliable suppliers to ensure that the quality of the material meets the relevant standards and customer requirements.

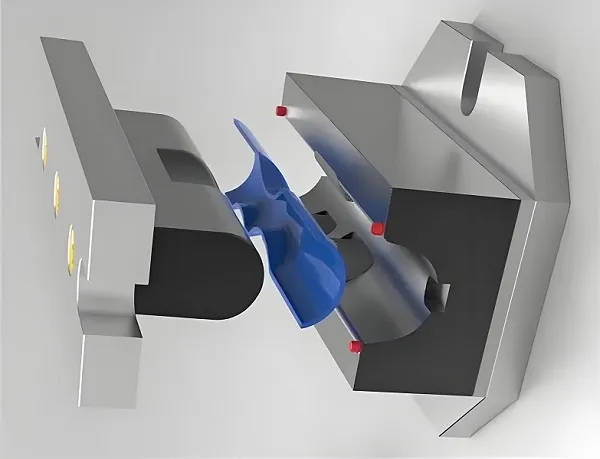

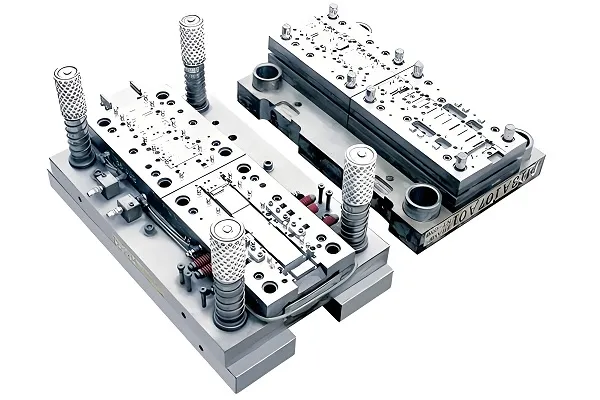

●Mold design and manufacturing

Mold design: According to the design drawings, carry out the detailed design of the mold. The mold design needs to consider factors such as parting surface, gate position, cooling system, ejector mechanism, etc. to ensure smooth injection molding and smooth demolding of products.

Mold manufacturing: Use advanced processing equipment and technology to manufacture the molds according to the design drawings. After the mold manufacturing is completed, strict inspection and mold testing are required to ensure that the precision and performance of the mold meet the requirements.

Injection Molding

Selection of injection molding machine: According to the size, shape and material requirements of the parts, select the appropriate injection molding machine. The selection of injection molding machine should consider its injection volume, clamping force, plasticizing capacity and other parameters.

Setting of injection molding process parameters: set the appropriate injection molding process parameters, including injection pressure, injection speed, holding time, cooling time, etc.. These parameters should be adjusted and optimized according to the fluidity of the material, mold structure and product requirements.

Injection molding: After heating the ABS material to a molten state, it is injected into the mold through the high pressure of the injection molding machine. After a period of cooling and curing, the mold is opened to remove the molded part.

●Post-processing and Inspection

Post-processing: Perform necessary post-processing on the injection molded parts, such as removing flying edges, grinding, polishing, etc., to improve the surface quality and aesthetics of the parts.

Quality Inspection: Carry out comprehensive quality inspection on the completed post-processing parts, including dimensional measurement, appearance inspection, performance test, etc.. Ensure that the parts meet the design requirements and customer expectations.

Packing and Shipping

Packaging: Properly pack the parts that have passed the inspection to prevent them from being damaged during transportation. Packing materials should be selected to prevent shock, moisture and scratches.

Shipment: Ship the packaged parts to customers according to the time and method agreed in the contract. Meanwhile, provide necessary instructions for use and after-sales service information.

To sum up, customized ABS injection molded parts is a complicated and delicate process, which requires manufacturers to have professional technical strength, rich experience and strict quality management system. By following the above process and points, you can ensure that the customized ABS injection molded parts have good quality and performance.

3. Application areas of ABS injection molded parts

ABS injection molded parts are deeply used in many fields due to their excellent performance and wide applicability. The following are the main application areas of ABS injection molded parts:

●Automotive industry

ABS injection molded parts occupy an important position in the automotive industry, used in the manufacture of body parts, interior parts, instrument panels, door panels, lampshades and so on. Its strength, impact resistance and chemical resistance make it an ideal material for automotive parts manufacturing. For example, key parts such as automotive instrument panels, bumpers, and inner door panels are often manufactured using ABS injection molding technology.

● Electronics and electrical appliances

ABS injection molded parts are also widely used in electronics and electrical appliances. They are used to manufacture housings, panels, switches, sockets, brackets for electronic devices, etc. The electrical insulation and processability of ABS make it an indispensable material in the electronics field. For example, the housings and internal supports of electronic products such as televisions, computers, and cell phones are often manufactured using ABS injection molding technology.

● Household appliances

ABS injection molded parts are equally important in the household appliance field. They are used to make washing machine housings, refrigerator parts, vacuum cleaner parts, etc. The appearance and texture of ABS, as well as its resistance to chemicals and abrasion, are critical to the home appliance industry. For example, the inner tubs and housings of washing machines and the door panels of refrigerators are often manufactured using ABS injection molding technology.

Construction and Building Materials

ABS injection molded parts are increasingly used in the construction and building materials sector. They are used for window and door frames, pipes, exhaust fans, wall coverings, etc. The weather resistance and durability of ABS make it suitable for both outdoor and indoor building materials. For example, window and door frames and interior decorative panels in some high-end buildings are often manufactured using ABS injection molding technology.

● Medical Equipment

ABS injection molded parts are also widely used in the medical equipment field. They are used in housings, panels, brackets, etc. The antimicrobial, easy-to-clean, and biocompatible properties of ABS make it a popular material in the medical industry. For example, control panels and housings for some medical devices are often manufactured using ABS injection molding technology.

● Toy Manufacturing

ABS injection molded parts are also important in toy manufacturing. Because ABS has good impact resistance, surface gloss, and plasticity, it is commonly used in the manufacture of toys, models, and game equipment. For example, many toy products such as children’s toys and model cars are often manufactured using ABS injection molding technology.

Xiamen Goldcattle Custom ABS Injection Molding Parts Service FAQ

How do I start the process of customizing ABS injection molded parts?

A: To begin the process of customizing ABS injection molded parts, you will first need to communicate with our professional team to define your specific needs, including the size, shape, material grade, quantity, and any special performance requirements of the part. We will make an initial assessment of your needs and provide recommendations for customization options.

● During the customization process, how do you ensure that the design of the part meets the requirements?

A: During the customization process, we will work closely with you to ensure that the design of the part exactly meets your needs. Our designers will use CAD software for 3D modeling, and make modifications and optimizations based on your feedback. We will also conduct a mold design review to ensure that the mold will produce a part that meets the design requirements.

● How long does it take to make a mold for an ABS injection molded part?

A: The time it takes to make a mold depends on a number of factors, including the complexity of the part, the accuracy requirements of the mold, and our current production load. Generally speaking, simple mold making may take a few weeks, while complex molds may take weeks or even months. We will try our best to shorten the mold making cycle time according to your requirements and schedule.

●How do you control the quality of ABS injection molded parts?

A: We strictly control the quality of ABS injection molded parts and ensure product quality through the following measures:

Using high quality ABS raw materials.

Adopting advanced injection molding machines and molds to ensure the stability and precision of the injection molding process.

Implementing strict production process control, including the monitoring and adjustment of parameters such as temperature, pressure and time.

Conduct comprehensive quality inspection of finished products, including dimensional measurement, appearance inspection, and performance test.

●Can you provide small-lot trial production service?

A: Sure. We offer small-lot trial production services so that you can evaluate the quality and performance of your parts before formal mass production. Small-lot trial production can help you identify potential problems and make timely adjustments and optimizations.

● How is the price of a custom ABS injection molded part determined?

A: The price of a custom ABS injection molded part is determined by a number of factors, including the complexity of the part, the cost of the material, the cost of making the mold, the production quantity, and the cost of labor. We will quote a price based on your specific needs and offer competitive pricing whenever possible.

● What is the lead time?

A: Delivery time depends on several factors, including mold making time, production lead time, and logistics and transportation. We will work out a detailed delivery plan according to your requirements and schedule, and deliver on time as much as possible. At the same time, we will keep communicating with you to inform you of the production progress and delivery status in time.