3/4/5 Axis Rapid Prototype CNC Precision Metal Parts

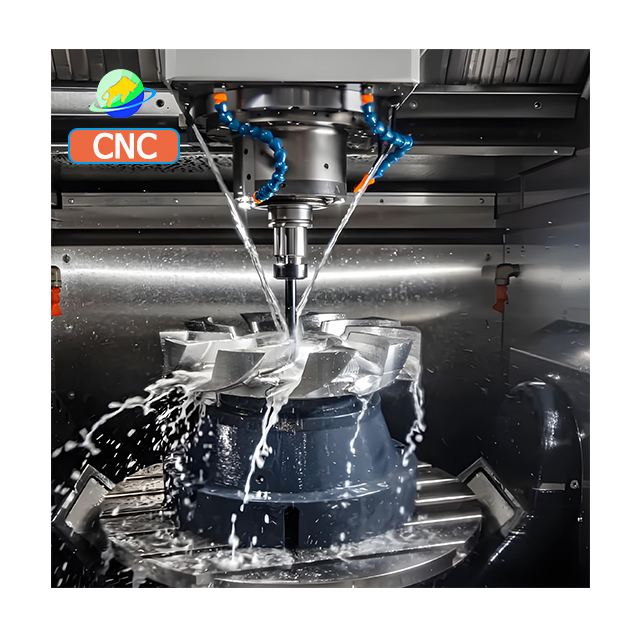

Processing Capabilities

Supported Number of Axes: 3 – axis/4 – axis/5 – axis simultaneous machining

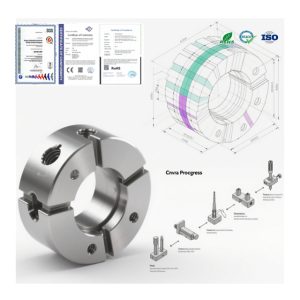

Maximum Workpiece Size: 1500×800×500mm (Customizable and expandable to 2000mm)

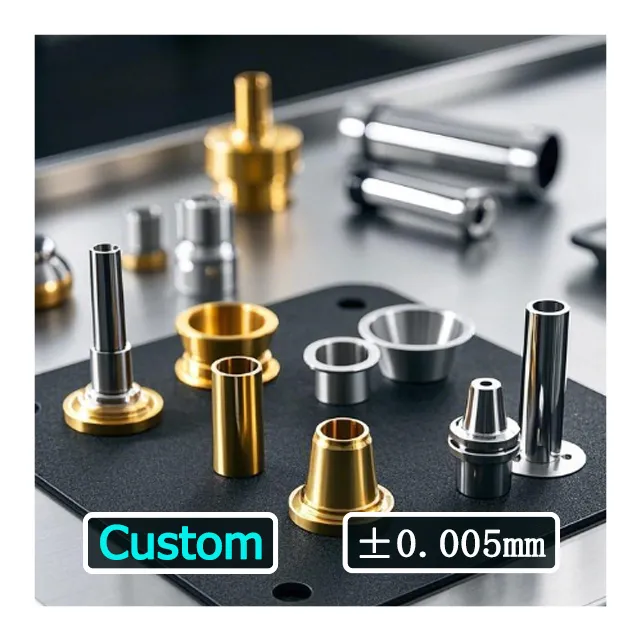

Processing Accuracy: ±0.005mm (Regular), ±0.002mm (High – precision mode)

Surface Roughness: Ra0.1μm (Mirror polishing), Ra0.2 – 3.2μm (Regular processing)

Applicable Materials

Aluminum Alloys: 6061/7075/ADC12 (Minimum wall thickness for thin – walled parts is 0.3mm)

Stainless Steels: 304/316L/17 – 4PH (Hard – state machining supported)

Titanium Alloys: TC4/Gr5 (Including inert gas protection process)

Others: Brass H59/H62, Nickel – based Superalloys (Inconel 718)