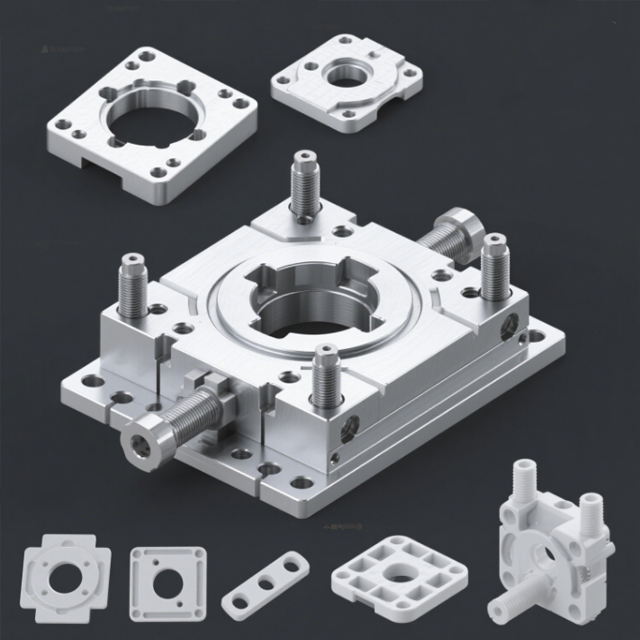

Custom MJ-08 Thermoplastic Injection Mold

Place of Origin : XiaMen, China

Brand Name : JSD

Model : MJ-08

Model : Injection Molding

Product Material : Plastic

Material : PP, PC, PS, PA46, POM, PE, PU, PVC, ABS, PMMA, etc.

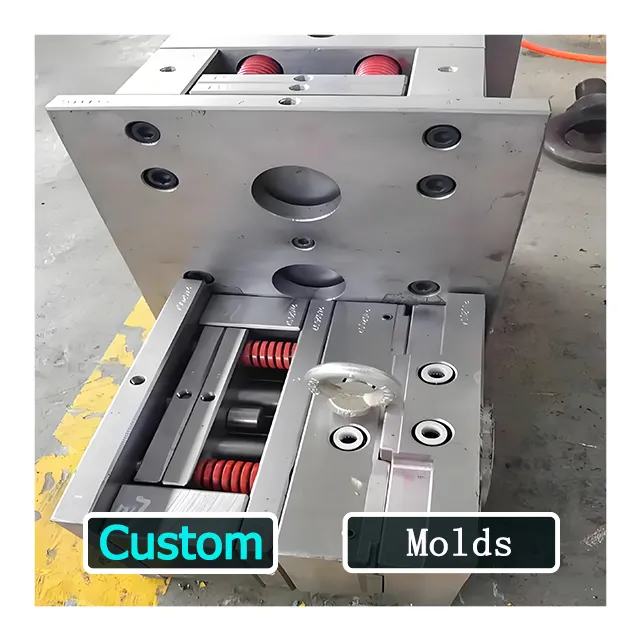

Cavity : single or multi-cavity

Color : white, black, grey or customized color

Product Name : Injection Mold

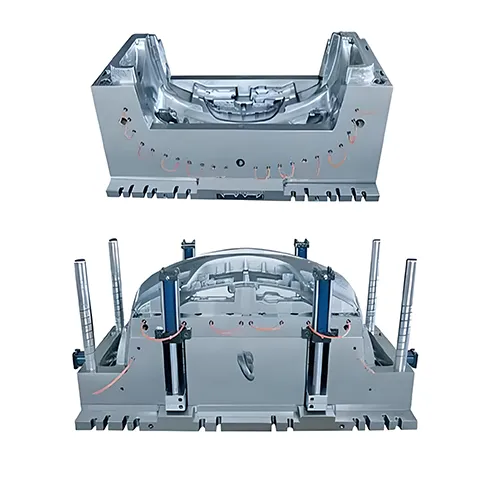

Application : Household products, electronic products, automotive parts, OME and high performance products, etc.

Mold Structure : Plastic injection mold

Surface Finish : Polished, textured, plated, painted, slip-printed, etc.

Service : OEM Customized Injection Molding Service

Keywords : Injection Molding Service