As an important part of automobile manufacturing, the quality of automobile plastic injection molding parts directly affects the overall performance and safety of the car. Through scientific design, reasonable production process and strict quality control, high quality and high performance automotive plastic injection molded parts can be produced to meet the development needs of the automotive industry. In the future, with the continuous progress of material science, injection molding process and automation technology, the application prospects of automotive plastic injection molding parts will be more broad.

1. Plastic injection molding parts design

1.1 Material selection

According to the use environment, performance requirements and cost considerations of automotive parts, choose the appropriate plastic materials. Commonly used materials include ABS, PP, PC/ABS, PA and so on.

Consider the material’s weather resistance, corrosion resistance, strength, toughness and other performance indicators to ensure that the injection molded parts meet the requirements of automotive use.

1.2 Structure design

Optimize the structure of the injection molded parts to reduce the wall thickness difference and avoid defects such as shrink marks and warping.

Design reasonable demolding slope, reinforcement, rounded corners and other structural elements to improve the molding quality and mold life of injection molded parts.

Consider the assembly relationship to ensure that the injection molded parts and other parts of the matching accuracy and assembly convenience.

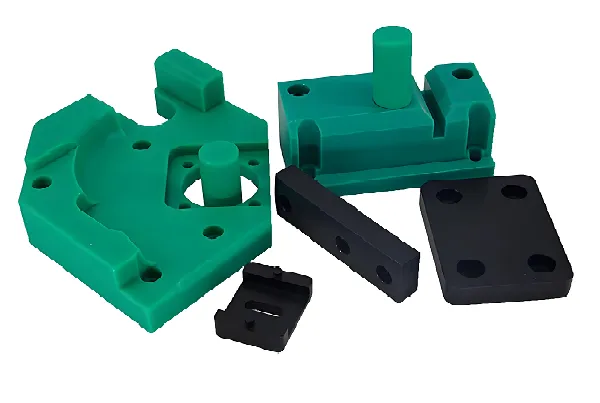

1.3 Mold design

According to the shape and size of the injection molded part, design a reasonable mold structure, including parting surface, gate position, cooling system and so on.

Adopt high-precision processing technology to ensure the dimensional accuracy and surface quality of the mold.

Equipped with necessary ejector mechanism and auxiliary devices to ensure the smooth demolding of injection molded parts.

2.Automotive plastic injection molding parts production process

2.1 Mould preparation

Check the mold: confirm the mold model, size and production plan is consistent, check the appearance of the mold without damage, no corrosion.

Clean the mold: use special cleaner to clean the surface of the mold thoroughly, remove oil and impurities, to ensure the surface finish of the mold.

Installation of molds: according to the operating procedures of the injection molding machine, install the molds on the injection molding machine, to ensure that the molds are installed firmly and accurately positioned.

Debugging the mold: carry out the debugging of the mold, check whether the opening and closing action of the mold is smooth, whether the ejector mechanism is working normally, and whether the temperature setting of the mold is reasonable.

2.2 Raw material preparation

Raw material inspection: check the raw material type, specification and production requirements, check whether the raw material packaging is intact, no moisture, deterioration phenomenon.

Drying: according to the characteristics of raw materials for the necessary drying process to ensure that the moisture content of raw materials in line with the requirements of injection molding.

Ingredients mixed: according to the formula proportion of accurate weighing of raw materials, and mixing to ensure stable quality of raw materials.

2.3 Equipment inspection

Inspection of injection molding machine: check whether the parts of the injection molding machine are intact, whether the hydraulic system, electrical system is normal, whether the heating system reaches the set temperature.

Auxiliary equipment check: check whether the robot, conveyor belt, cooling system and other auxiliary equipment are running normally to ensure the smooth production process.

3. Injection molding process control

3.1 Injection molding process setting

According to the product drawings and process requirements, set the injection molding machine injection pressure, injection speed, holding time, cooling time and other process parameters.

Debug the injection molding machine to ensure that the process parameters are stable and reliable, product quality in line with standards.

3.2 Injection operation

Feeding: add the dried raw materials into the hopper of the injection molding machine to ensure a continuous and stable supply of raw materials.

Injection: start the injection molding machine, according to the set process parameters for injection operation, pay attention to observe the injection process of pressure, temperature and other parameters change.

Pick up: After the injection is completed, use the robot or manually remove the product from the mold and place it to the designated location for cooling.

3.3 Process monitoring

Appearance Inspection: Perform preliminary appearance inspection of the injection-molded products, such as whether there are shrink marks, fusion marks, scratches and other defects.

Size inspection: Use measuring tools to inspect the key dimensions of the product to ensure that the product dimensions are in accordance with the requirements of the drawings.

Performance testing: According to the product performance requirements for testing, such as strength, toughness, weather resistance and so on.

4.Product Inspection and Packaging

4.1 Product inspection

Conduct full inspection or sampling inspection on the injection-molded products to ensure that the product quality meets the standards.

Marking, isolation and treatment of non-conforming products, analyze the reasons and take improvement measures.

4.2 Product packaging

Pack the products in accordance with the packaging standard book to ensure that the packaging materials meet the requirements of environmental protection.

Stick the product label and certificate of conformity on the package, indicating the product name, specification, quantity, production date and other information.

5.Application Cases

5.1 Car bumper: It is injection molded with high-strength and impact-resistant plastic material, which has excellent anti-collision performance and aesthetics.

5.2 Dashboard trim panel: realized complex shapes and fine textures through precision injection molding process, to enhance the grade of car interior decoration.

5.3 Hood cover: adopting lightweight design to reduce car weight and improve fuel economy.

Auto Plastic Injection Molding Parts FAQ

1. Why are automotive plastic injection molded parts widely used in automotive manufacturing?

A: Automotive plastic injection molded parts are widely used in automobile manufacturing due to their advantages of light weight, low cost, high design freedom, corrosion and wear resistance. They not only help to reduce the overall weight of automobiles and improve fuel economy, but also show advantages in the manufacture of complex shapes and fine textures to meet the aesthetic and functional needs of automobile interiors and exteriors.

2. What are the main materials for automotive plastic injection molded parts?

A: The main materials for automotive plastic injection molded parts include ABS (acrylonitrile-butadiene-styrene copolymer), PP (polypropylene), PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene copolymer), PA (nylon) and so on. These materials have good mechanical properties, processing performance and weather resistance, and can meet the use of different parts of the automobile requirements.

3. What are the factors to be paid attention to in the design of automotive plastic injection molded parts?

A: In the design of automotive plastic injection molded parts, the following factors need to be paid attention to:

Material selection: Select the suitable plastic material according to the use environment and performance requirements of the parts.

Structural design: Optimize the structure of the injection molded part to reduce the wall thickness difference and avoid defects such as shrinkage marks and warping; design reasonable demolding slope, reinforcement, rounded corners and other structural elements; consider the assembly relationship to ensure that the injection molded part and other parts of the matching accuracy and assembly convenience.

Mold design: design reasonable mold structure according to the shape and size of the injection molded part, including parting surface, gate position, cooling system, etc.; ensure the dimensional accuracy and surface quality of the mold; equip with necessary ejector mechanism and auxiliary devices.